The Ultimate Guide to Full Ceramic Bearings In Water Processing, Water Filtration and Liquid Handling (Part 2)

Generally speaking, ceramic materials are extremely durable. Most of them are man-made using chemical processes, and consequently can withstand extremely high temperatures and corrosive materials.

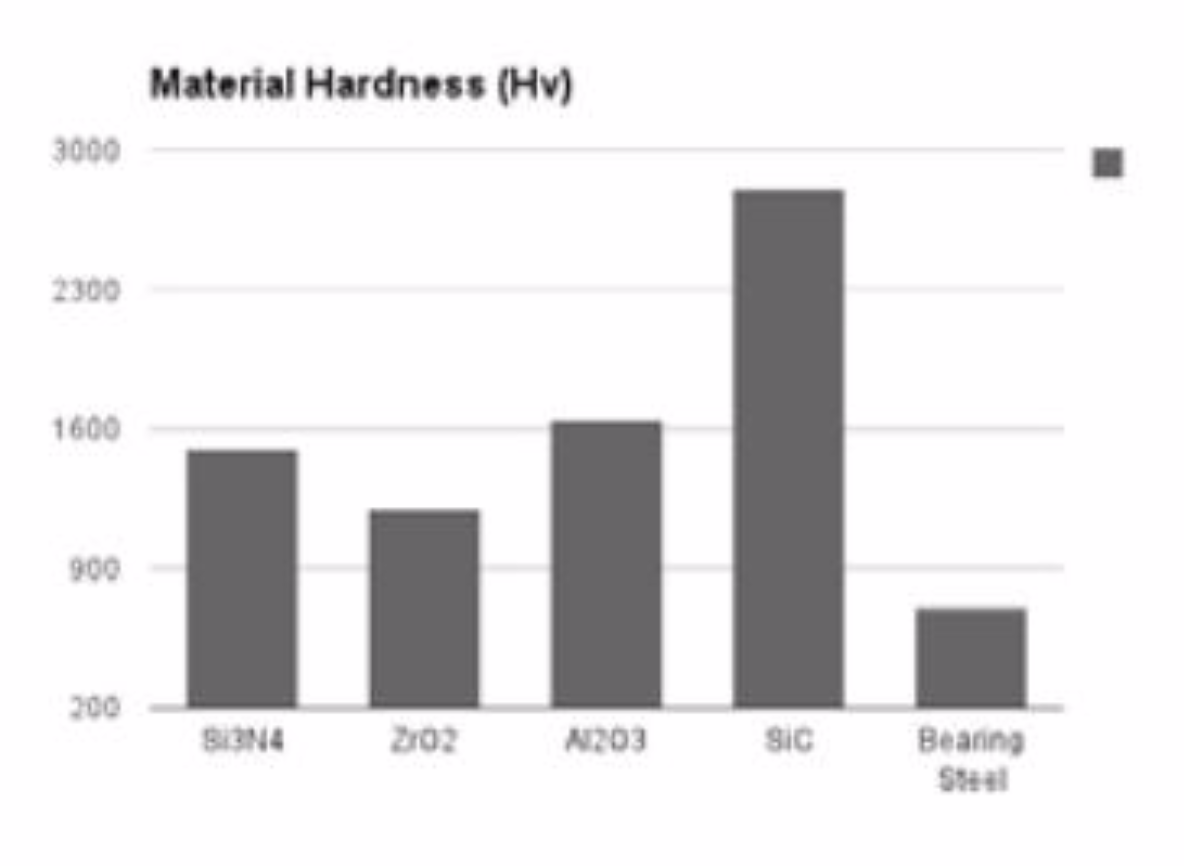

Full ceramic bearings have a much longer lifespan than hybrid ceramic bearings or the steel alternatives, particularly when they aren’t placed under a considerable load. This can be attributed to many properties of full ceramic bearings. Firstly, ceramics are much stronger. As a result, the balls or races of the bearing do not become distorted when placed under load. However, the superiority of full ceramic material increases with the load, and full ceramic materials are still at risk of premature failure in these cases.

The main limitation of ceramic bearings if the fact they can be quite brittle. Consequently, you must analyze the load to ensure the chose material can cope with the stress. Zirconia Oxide will handle large loads better than the rest of the full ceramic materials.

Ensuring Extensive Lifespan of Bearings

Generally speaking, ceramic materials are extremely durable. Most of them are man-made using chemical processes, and consequently can withstand extremely high temperatures and corrosive materials.

Full ceramic bearings have a much longer lifespan than hybrid ceramic bearings or the steel alternatives, particularly when they aren’t placed under a considerable load. This can be attributed to many properties of full ceramic bearings. Firstly, ceramics are much stronger. As a result, the balls or races of the bearing do not become distorted when placed under load. However, the superiority of full ceramic material increases with the load, and full ceramic materials are still at risk of premature failure in these cases.

The main limitation of ceramic bearings if the fact they can be quite brittle. Consequently, you must analyze the load to ensure the chose material can cope with the stress. Zirconia Oxide will handle large loads better than the rest of the full ceramic materials.

Electrical Insulation With Ceramic Bearings

The ceramic bearings are also non-magnetic, and with the exception of Silicon Carbide, provide good electrical insulation. Silicon Nitride offers the best electrical resistance, but is closely followed by Zirconia Oxide, which is readily available and fits within most budgets.

Improved Performance of Bearings in Water and Other Liquids

Research has demonstrated that full ceramic bearings perform better than any alternatives when placed in water. Depending upon the material used, the lifespan can be up to 70 times longer than stainless steel bearings, a common alternative. The best ceramic materials for use in water processing environments are Silicon Nitride and Zirconia Oxide. Hybrid ceramic bearings also perform better than steel, but their lifespans are significantly shorter than full ceramic materials, which in some cases have a lifespan 5 times longer.

Resistance to Corrosion

It is not feasible to use metallic bearings within industries handling water or other liquids, as they will corrode rapidly. When selecting the most appropriate material for the ceramic bearings, you should also consider the types of liquids the bearings will encounter. If the bearings will be used in environments containing corrosive materials, the lifespan will be significantly altered. Silicon Nitride offers good resistance to the majority of chemicals, so is often a good choice when the budget permits.

Temperature Considerations

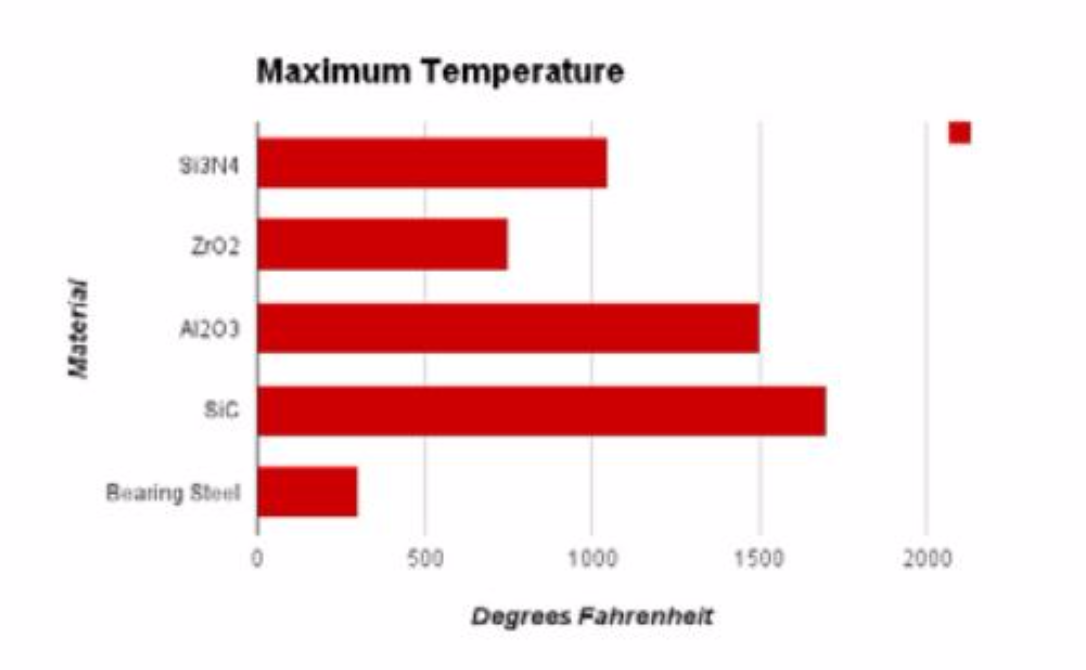

When deciding which material to use, it’s important to consider the technical properties of each material to evaluate their suitability. One of the most important aspects to consider, particularly when working with liquids that may reach high temperatures, is the temperature of the environment in which you will be using the bearings. Silicon Nitride can be used in environments reaching up to 1050.F, without loading. However, this can change significantly when used in industries handling liquids, as the bearings can encounter significant loading.

The coefficient of thermal expansion is possibly a more useful characteristics, as it provides you with an indication of the materials ability to cope in response to heating and cooling. Full ceramic bearings offer relatively low coefficients, compared to the non-ceramic alternatives. For example, Silicon Nitride has a coefficient of 3.2 x 10-6/k and Silicon Carbide offers 3 x 10-6/k. Zirconia Oxide and Aluminum Oxide are considerably higher, at 10.5 x 10-6/k and 8.5 x 10-6/k respectively, but both of these are much lower than bearing steel, which has a coefficient of 12.5 x 10-6/k. In environments with considerable temperature changes. Silicon Nitride and Silicon Carbide are the best choices. These materials also offer good thermal shock resistance (up to 1112.F in Silicon Nitride, and 752.F in Silicon Carbide), which indicates minimal risk of fracture due to the changing temperatures.

Resistance To Fracture Under Load

The material’s ability to resist fracture is essential when used with liquids, such as water processing, as pressure is increased when submerged. Therefore, another characteristic that must be considered is fracture toughness. This indicates how capable the material is at resisting fractures in high-pressure environments. Zirconia Oxide offers the best resistance, with a fracture toughness of 10 MPA*m1/2, closely followed by Silicon Nitride at 6.2 MPA*m1/2. These are consequently the best materials to use in a high-pressure environment, where the risk of cracks and fractures is high.

The development of mechanical equipment for use in wet environments is no easy task, and selecting the right materials is vital to ensure the success of your business. Mistakes can be expensive, so it’s important to understand the properties of the available resources. When it comes to bearings, metallic or hybrid options are simply not an option if significant contact with water is expected. Instead, full ceramic materials should be used to ensure the machinery will be built to last, and will operate efficiently for the duration of its use.

The Ultimate Guide to Full Ceramic Bearings In Water Processing, Water Filtration and Liquid Handling (Part 1)

Bearings are essential mechanical components of machinery used in a variety of industries. A bearing’s purpose is to help facilitate desired motion, limit undesired movement, and reduce friction. Bearings are thought to date back as far as the ancient Egyptian era, when wooden bearings were used to assist with the movement of heavy objects. Since then, the concept has developed considerably; bearings now come in a variety of forms, and are made from many different types of materials.

Bearings are an essential component in the majority of mechanical designs and equipment. It is important to consider the most effective materials when designing industrial machinery, especially in applications where water, or other liquids are present. Many materials will be unable to overcome the challenges associated with operating in a wet or corrosive environment.

To overcome the challenges faced by industries involved in water processing, water filtration and liquid handling, full ceramic bearings should be used. This paper will outline the properties of full ceramic bearings, and enable you to determine whether they are the most appropriate type for your mechanical processes.

Bearings are essential mechanical components of machinery used in a variety of industries. A bearing’s purpose is to help facilitate desired motion, limit undesired movement, and reduce friction. Bearings are thought to date back as far as the ancient Egyptian era, when wooden bearings were used to assist with the movement of heavy objects. Since then, the concept has developed considerably; bearings now come in a variety of forms, and are made from many different types of materials.

Bearings are an essential component in the majority of mechanical designs and equipment. It is important to consider the most effective materials when designing industrial machinery, especially in applications where water, or other liquids are present. Many materials will be unable to overcome the challenges associated with operating in a wet or corrosive environment.

To overcome the challenges faced by industries involved in water processing, water filtration and liquid handling, full ceramic bearings should be used. This paper will outline the properties of full ceramic bearings, and enable you to determine whether they are the most appropriate type for your mechanical processes.

Comparing Full Ceramic Materials’ Properties

There are a number of ceramic materials that can be used to produce full ceramic bearings. While these share a number of properties, they also offer distinct characteristics, which will help you to determine the most suitable material for your machinery. Here’s a guide to the most common materials used to produce full ceramic bearings:

Zirconia Oxide (ZrO2)

Zirconia Oxide was first used in the 1960s. It was used in space travel, creating a thermal barrier to enable space shuttles to enter the Earth’s atmosphere. It copes well with high temperatures, but doesn’t handle thermal shock resistance to the same extent as alternative ceramic materials, such as Silicon nitride. It’s best used in high temperature environments that involve minimal loads. It’s highly resistant to corrosion, which makes Zirconia Oxide the perfect choice for use with highly corrosive liquids. It’s an incredibly strong material, which also makes it ideal for use in mechanical applications involving fracture risk. ZrO2 has an operating temperature range of -85.C to 400.C

Silicon Nitride (Si3N4)

Silicon Nitride is a ceramic material produced using a series of chemical reactions, creating a full ceramic material with distinctive properties. The material is dark in color, and is one of the most superior types of ceramic material in terms of quality and durability. This material is relatively expensive, but the extra cost is worthwhile if you’re looking for something that can withstand high temperatures and harsh mechanical conditions. In terms of withstanding high temperatures, silicon nitride is superior to alternative metallic solutions, and it has a lower thermal expansion coefficient than many alternative ceramic materials. This makes it an excellent choice when thermal shock resistance is a high priority. Si3N4 has an operating temperature range of -100.C to 900.C

Aluminum Oxide (Al203)

Aluminum Oxide is the most popular ceramic ball material, and its common uses expand far beyond the reams of ceramic bearings. It’s produced through the process of calcination of aluminum hydroxide, which creates a durable and highly resistance ceramic material. This material is best known for its high compression strength, and its ability to resist corrosion when faced with a variety of abrasive chemicals, even when the environment involves extremely high temperatures. Less expensive than some of the alternative ceramic materials, aluminum oxide is readily available and is the most popular choice ceramic bearing for projects in which the available budgets are limited.

Silicon Carbide (SiC)

Silicon Carbide is produced by chemically combining carbon and silicon atoms. It has excellent mechanic properties, which makes it a fantastic choice for use in the creation of bearings. Grains of silicon carbide have been used for many years as an abrasive, most commonly in the form of sandpaper. However, these grains can be combined through sintering to create the highly durable ceramic material used to create silicon carbide bearings. This is a strong, durable ceramic material with a low density, low rate of thermal expansion, and fantastic thermal shock resistance, making it suitable for use in a wide variety of applications.

How To Prevent Pulley Slippage

There are a variety of methods used to attach pulleys to shafts. Knowing the advantages and disadvantages of each one will help you make a better choice when installing drive components into your assembly. Using the appropriate method for your application can go a long way in preventing damage and possible equipment failure. Consideration should also be given to field service needs.

There are a variety of methods used to attach pulleys to shafts. Knowing the advantages and disadvantages of each one will help you make a better choice when installing drive components into your assembly. Using the appropriate method for your application can go a long way in preventing damage and possible equipment failure. Consideration should also be given to field service needs.

Controlled tolerances between the shaft and pulley prevent slipping and can be achieved through various mounting devices or fastening methods. Type of connections between shaft and pulley:

- Set-screw

- Fairloc

- Press-fit

- Shaft-lock

- Shaft extenders

- Clamp

Structure: advantages and disadvantages of each:

Set-screw type connection is a simple, in expensive way to connect a pulley to a shaft. The pulley requires an additional extension (Hub) on which, perpendicular to the direction of the shaft a hole or holes are drilled and tapped.

Drilling and tapping can be performed on any type of material the pulley is made of, most common are aluminum, stainless steel, steel, and plastics, with a metal or reinforced hub.

Disadvantages: require additional axial space because of the hub's projection; torque transmission is limited in comparison to press-fit and shaft lock types. In addition, different types of set screw tips can damage the surface of the shaft.

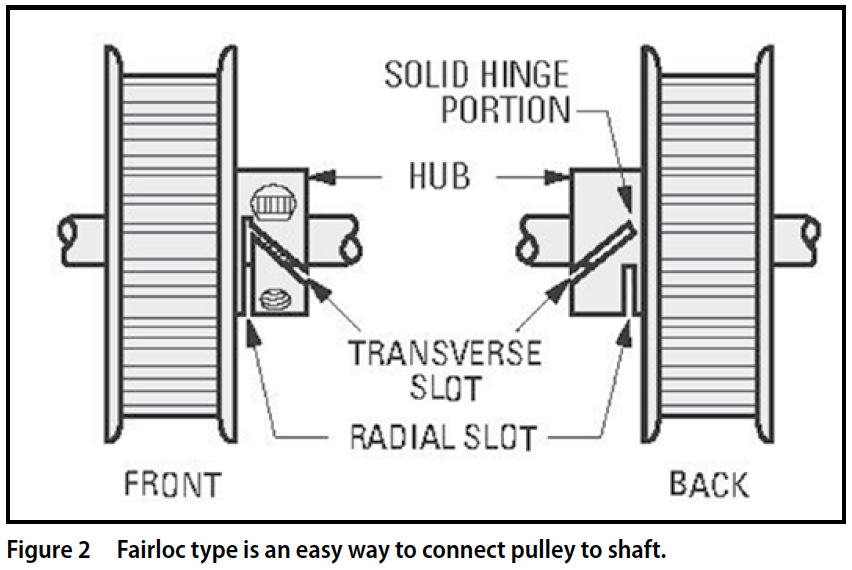

Fairloc Type is an easy way to connect the pulley to the shaft.

Two slots are machined into the hub - one oriented radially, the other angularly - to create a transverse wedge which remains attached to the solid portion of the hub on one side. The resultant cantilevered clamping section has a tapped hole to accept a cap screw which passes through a clearance hole in the solid portion of the hub, and into a threaded hole in the transverse wedge section. As the screw is tightened, the cantilevered section clamps the shaft securely.

The compact, self-contained design reduces misalignment and can be tightened and released repeatedly without marring the shaft. Produced in stainless steel, aluminum and brass, it is well suited for applications that require moderate torque and speed. For optimal performance Fairloc hubs require controlled tolerances between the shaft and pulley (suggested clearance fit .0001"/.0008"). For high-torque/high-speed applications, shaft locks are a better option.

Press-fit type, especially for metal on metal, is a good option for applications requiring tight concentricity/runout. This method performs well in low/moderate torque (20-30 lbs x in.) applications, even for high rotational speeds. Good for devices where space constraint is a concern.

Disadvantages: Requires very precise tolerances on the bore of the pulley and on the pilot surface of the shaft. Not all combinations of materials provide the same torque capacity of the press-fit

Shaft-lock type is a very robust way to connect a pulley to a shaft; good for high-speed applications as well. It is recommended for mechanisms where axial space is of concern; doesn't require extremely precise tolerances on the pilot surfaces. These devices are made of various types of metals (steel is preferred).

Disadvantages: a more expensive option (requires additional component, the shaft-lock). Some of the shaft-lock devices, especially the heavy duty ones, are not easily installed and even more difficult to uninstall.

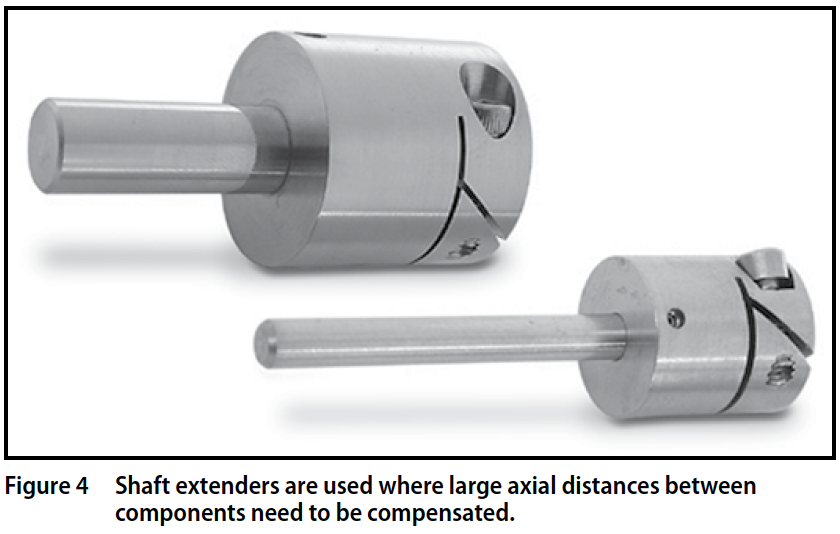

Shaft Extenders are used where large axial distances between components need to be compensated. When produced in stainless steel they provide the best performance for high-torque (70-80 lbs x in.) and high-speed applications.

Disadvantages: requires high precision shafting and very tight concentricity bore and the shaft O.D.

Clamp type requires additional clamp to connect a split hub pulley and a shaft. Clamps come in a variety of configurations; balanced clamps are used for high-torque applications.

Disadvantages: additional component - the clamp. Requires controlled tolerances on pilot surfaces, some of the constructions are difficult to assemble. Usage of clamps has declined as easier to use connecting methods have been developed.

Applications:

- Set-screw: in mechanisms used for shop manual tools

- Fairloc: aerospace, avionics, medical, printing, scanning devices

- Shaft-lock: power tools, oil industry

- Shaft extenders: drilling devices

When attaching the pulley to a shaft you have a number of choices; one method may work better in your application than another. It is important to have a basic understanding of your drive system and keep the following points in mind: torque, speed requirements, accessibility, material and cost.

Darbar Company is Pakistan's leading Power Transmission Solution provider, mainly specializing in Bearings, Roller Chains and Timing Belts. Give us a call to find out what products we carry.

The original article can be found at the Power Transmission Engineering blog here

Bearing The Brunt of Earthquakes

According to FEMA study back in 2000, America suffers $4.4 billion in losses due to earthquakes every year. While that’s a drop in the bucked for their $16 trillion plus GDP, it’s still a substantial amount of money, and some people are working on to lessen those losses. One group is Earthquake Protection Systems (EPS), a company that is designing bearings to better protect buildings from earthquake damage.

According to FEMA study back in 2000, America suffers $4.4 billion in losses due to earthquakes every year. While that’s a drop in the bucked for their $16 trillion plus GDP, it’s still a substantial amount of money, and some people are working on to lessen those losses. One group is Earthquake Protection Systems (EPS), a company that is designing bearings to better protect buildings from earthquake damage.

According to EPS Vice President, Dr. Anoop Mokha, standard building regulations are inherently flawed, as they insist that a building be capable of remaining standing during an earthquake, but say little about what state the building needs to be in beyond that. This means that while we’ve gotten pretty good at making sure buildings don’t collapse and hurt people during earthquake, there’s still a high number of buildings that are being crippled and rendered derelict by them. As an example, Mokha pointed to an earthquake that happened in New Zealand in 2010. Only two buildings collapsed during the quake, but the event still left 70 percent of affected buildings so badly damaged that they had to be torn down.

Ever since the company first opened its doors in 1985, EPS has been working to reverse that trend with a product they call a friction pendulum bearing, which is designed to not only keep buildings standing after an earthquake, but to keep them operable and livable.

“What we are doing is allowing engineers and owners to have sustainable structures they can walk in after an earthquake, they have no damage,” Mokha said.

The bearings are designed to absorb excess energy when the force of an earthquake exceeds a building’s acceptable horizontal load and safely dissipate it in the form of motion. This means that when an earthquake’s force would otherwise damage a building, the bearings allow the building’s foundation to physically move back and forth like a pendulum, finding an outlet to expend otherwise damaging levels of force.

EPS’s newest product, the Triple Pendulum Bearing, takes it a step further, with three different bearings in a single product all designed to resist different magnitudes of earthquakes, the bearings activate sequentially, so that only one bearing is active at any given time, but each bearing is ideally suited to different magnitude earthquakes, and when one bearing’s ability to resist the earthquake is overloaded, the next bearing immediately takes over.

“If the earthquake is weak, the bearing is weak,” Mokha said. “If the earthquake gets stronger, the bearing gets stronger.”

According to Mokha, products like Triple Pendulum Bearing are fairly standard in Japam, where earthquakes are a constant hazard, but are still only just catching worldwide as an effective countermeasure for earthquakes. Mokha estimates that previously, only about 10 percent of buildings in the U.S. used pendulum bearing or equivalent product, but that in recent years, that number may have risen as high as 15 or 20 percent and is still growing.

“What Elon Musk did with the electric car in the automotive industry, and now everyone is realizing the benefits… I believe we have crossed that threshold now, where people are realizing the benefits,” Mikha said.

You can contact Earthquake Protection Systems Directly by visiting their website: www.earthquakeprotection.com

Original article available at Power Transmission Engineering (be sure to subscribe for more industry insights): http://bit.ly/2m4lBe2

Bearing Research: Going To The Atomic Scale

This article provides insight into the four main lines of research through modelling at SKF: bearing steel, fatigue mechanisms, polymer design and tribology.

In the past few years SKF has been expanding its knowledge with the atomic scale simulation methods such as DFT, MD, and DPD, to understand how materials behave in its products. This has enabled and will continue to enable SKF to innovate and cope with ever-increasing technological challenges by ensuring that every atom is in the place it belongs.

This article provides insight into the four main lines of research through modelling at SKF: bearing steel, fatigue mechanisms, polymer design and tribology.

In the past few years SKF has been expanding its knowledge with the atomic scale simulation methods such as DFT, MD, and DPD, to understand how materials behave in its products. This has enabled and will continue to enable SKF to innovate and cope with ever-increasing technological challenges by ensuring that every atom is in the place it belongs.

Technology

Imagine if one could become so small that he or she could dive into solid materials and see the structure of the atoms – how the interact, move and respond when external force is applied and how the external temperature influences their properties and changes their structure. If this were possible one could better select, process and design the materials used to manufacture products and machines.

At the SKF Engineering and Research Centre (ERC) in the Netherlands, research is done with the objective of virtually diving into the materials that make up SKF’s products to achieve a better understand of their behavior. This enables SKF to respond to requests from customers, and more importantly, to develop new materials for its products that increase their quality, durability and other specific properties.

In most of the cases, the use of experimental methods is enough to gain sufficient understanding of how external constraints might affect the materials from which products are made and to find preventive and counteractive solutions.

Nevertheless, even with the use of state-of-the-art experimental techniques, it is simply not always possible to get sufficient understanding of the effect that certain phenomena can have on the materials. In addition, in some cases such as with a new material or product that in the design phase, being limited to the use of laboratory test tools is not always time-efficient or cost-effective. This is why computational methods are essential

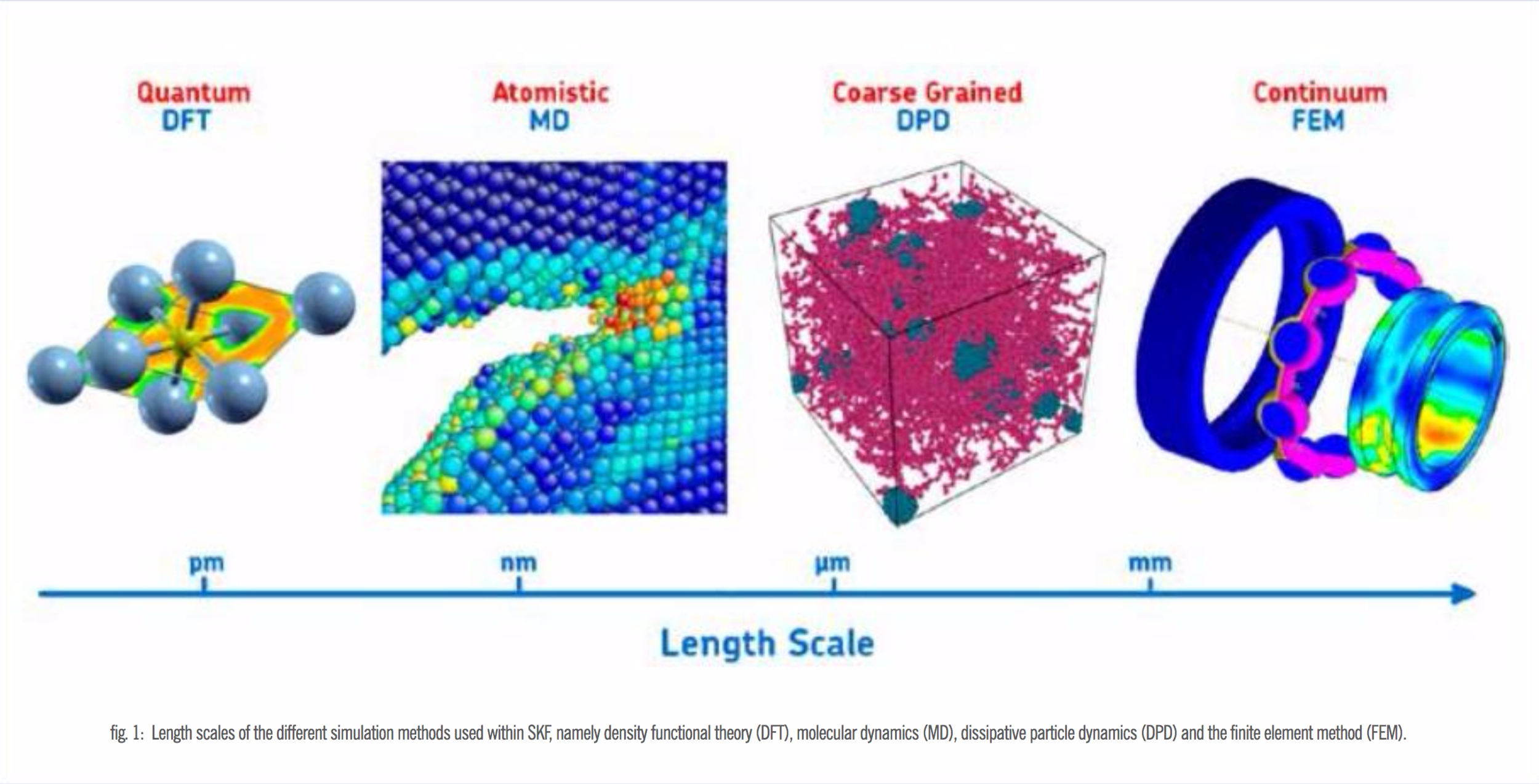

When it comes to mechanical parts, e.g., rolling bearings, most design issues can be worked out using “large scale” simulation techniques, such as the widely used finite element method (FEM). However, some special issues go beyond the capabilities of this modelling tool and require being treated with alternative mesoscopic and microscopic simulation methods.

To get a thorough understanding of SKF’s products and be able to tackle the issues that might have an origin at particular time and length scales, scientists at SKF are constantly developing their know-how in the use and advancement of multi-scale simulation methods. This means that there are different tools (imagine magnifying glasses, all with a different magnifying power) that can be used to understand specific phenomena that determine the behavior of a material in application conditions. This is why the models that are applied at SKF range from quantum mechanical to continuum (fig.1).

The deeper one dives inside the material, the more calculation power and time are needed to make simulations. For this reasons, a high-performance computer cluster with 1,536 processors is being used in SKF facilities.

Currently, there are four major lines of research for which meso- and micro-scale methods are used.

Steel Design

The first line of research is part of the project “MultiHy”, short for Multiscale Modeling of Hydrogen Embrittlement. This project is led by a consortium formed by various European industrial and academic partners and is funded by the European Union. The initial motivation for this project is that there is ample experimental evidence that supports the idea that hydrogen decreases the fatigue life of bearings and structural steels. This effect of hydrogen is known within the technical jargon as hydrogen embrittlement. SKF’s main interest is MultiHy is to be able to predict how hydrogen diffuses into and through bearing steels and, more importantly, to discover how available hydrogen can be trapped and immobilized to neutralize the impact of hydrogen embrittlement on bearing service life.

Such simulations on hydrogen mobility and its effect on fatigue life complement other ongoing research dealing with various sources of hydrogen, e.g., humid environments and possible degradation of lubricants.

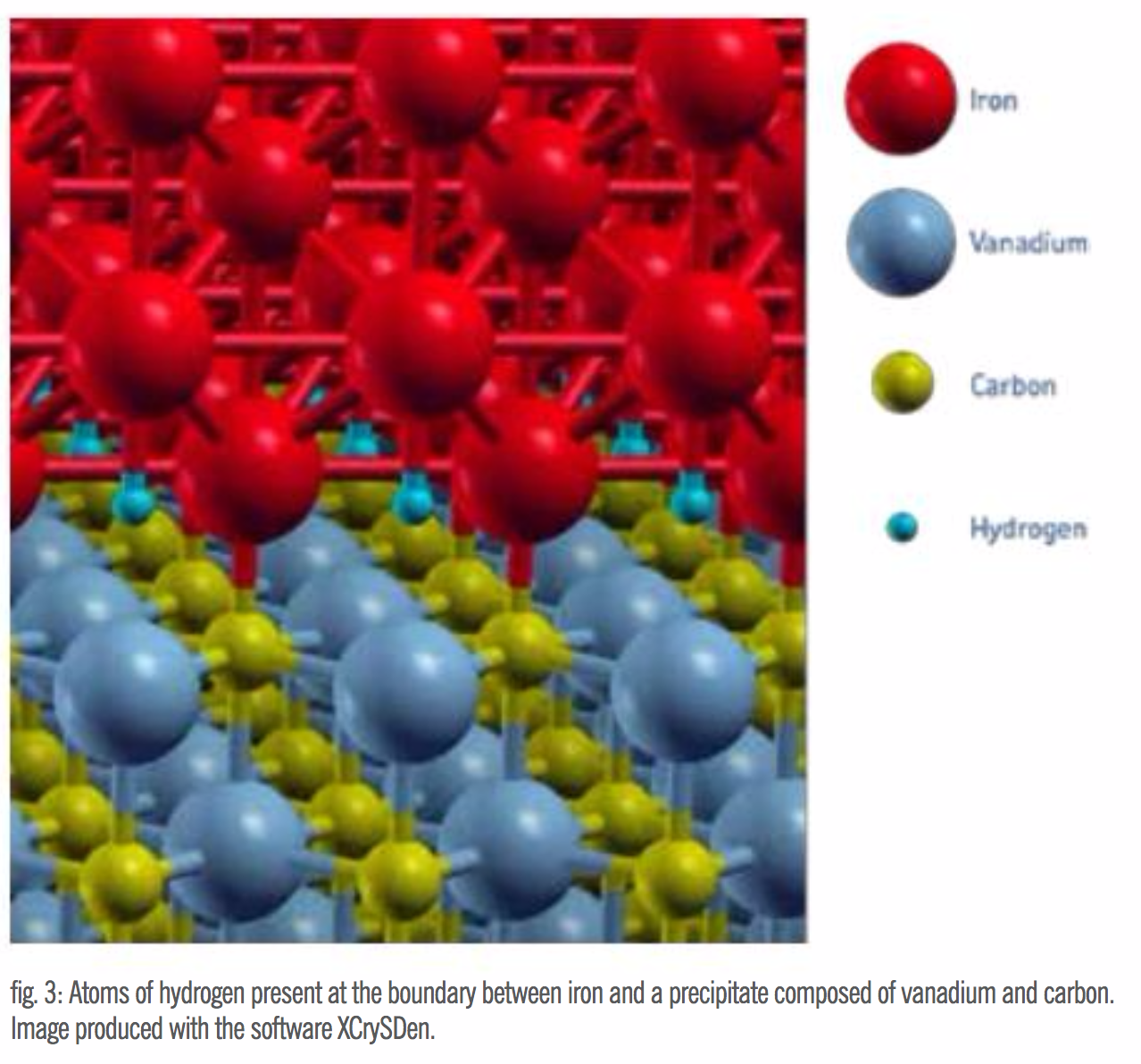

From the atomistic point of view, simulations are being carried out using a computational quantum mechanical modelling method called density functional theory (DFT), which is commonly used to investigate the electronic structure of many-body systems (fig.2). More specifically, simulations are being done to evaluate the mechanical properties and the influence of hydrogen in a new experimental vanadium-containing bearing steel (fig.3) in which hydrogen can be trapped to avoid embrittlement. The results of the MultiHy project can help with the final development of this new steel, so that it can be eventually considered for applications where hydrogen resistance is needed.

Fatigue Mechanisms

The second line of research is aimed at the atomic description of the microstructure of bearing steels and its influence on the behavior of the material when subjected to rolling contact fatigue. For this project, the molecular dynamics (MD) method is being used to study how the atoms move and interact with each other when a crack is initiating and propagating through bearing steel (fig.4). The understanding of this phenomenon will enable SKF to find ways to increase the life and overall performance of SKF products.

Polymer Design

The third application deals with the study of filled rubber materials used in the manufacturing of seals. The overall goal is to identify and quantify the physical phenomena taking place at different scales that influence the quasi-static and dynamic stress-strain behavior of filled rubber. This project is being carried out by SKF in collaboration with scientists from Tsinghua University in China and from the University of Barcelona in Spain.

Dissipative particle dynamics (DPD), a meso-scale simulation tool that enables analysis of the dynamic properties of fluids and polymers (fig.5) at scales that go beyond those that can be treated using MD, is used here. By employing DPD, the effect of various factors, such as the interaction between filler particles and polymer chains and the topological changes in the polymer network in the static and dynamic mechanical behavior of sealing materials, can be fully considered.

Tribology

The final application addresses the lubricated contact between two surfaces, such as that between a rolling element and a raceway in a hybrid bearing. The method used for this work is also MD. The goal is to explain the fundamental differences in friction and wear between steel/steel and steel/ceramic surfaces to improve the performance of hybrid bearings. Also, chemical reactions between the lubricant and the surfaces can be considered.

So far, the modeling has revealed that there are fundamental differences between steel/steel and hybrid contacts related to friction and wear. More importantly, the results have shown that hybrid contacts present lower friction than steel/steel contacts.

This article has been extracted from the latest edition of Bearing-News magazine