New Bearings Are Gateway To Digitalization And IIoT

Recorded data transfer via a gateway to the Schaeffler cloud, where engineers can take advantage of the company’s rolling-bearing domain expertise. For example, automated rolling bearing diagnosis and remaining useful life calculations can provide precise information on the condition of the bearing and, thus, of the machine being monitored. That, in turn, lets experts recommend specific follow-up actions. It will even be possible to use actual load data to make adjustments to machine operations and processes in real time.

In one case, measuring radial shaft displacement in the bearing lets the software determine the radial force on the sensor bearing. If the model for a specific powertrain is stored in the Schaeffler cloud as an algorithm in the Bearinx calculation software, then forces, displacements and torques on other bearings, gears and other machine elements can also be determined indirectly from these data. This means that the most important values for monitoring process parameters in machines and equipment are known, and that provides significant added benefits for the operator. For instance, information on overloading can be easily recorded and used to limit torques or even switch off the drive if necessary.

Or the concept of digitalizing production can include monitoring machine processes in terms of vibration, force, temperature and pressure and provide critical data for predictive maintenance. Sensors can record information on the operating conditions of individual bearing in a drivetrain and transfer these data to the cloud for analysis and evaluation. Maintenance technicians, in turn, can access the data worldwide via an Internet connection for a report on the machine’s condition at any time. Finally, operators can receive text messages about analyzed damage and can plan maintenance measures before sudden breakdowns occur.

The first range of VarioSense bearings is available for commonly used 6205 to 6210 Series ball bearings. The VarioSense bearings are supplied with an interface box for power supply (in a range from 4.5 to 30 V), signal processing and networking.

Interest from potential customers is wide-ranging, said the company. Suitable applications for the sensor bearings include pumps and electric motors, drives for agricultural and construction machinery, electric vehicles and fork-lift trucks to wind turbines, conveyors and elevators.

Rolling bearings are ideally suited for gathering information, noted Schaeffler officials, because they are located at the heart of a machine’s flow of force and, thus, exposed to all the loads. Combining them with domain expertise about rolling bearings in specific applications made available via the cloud lets this information be used to control processes in a targeted manner. The end results are maximum capacity utilization and optimized product quality. The prerequisite for this is a holistic and standardized infrastructure from the sensor through to the cloud, which Schaeffler now provides with its Smart EcoSystem.

Original article can be found here

Darbar Company is one of the leading suppliers of Power Transmission Products. Consumers in Pakistan looking for bearing products can contact us here

New Bearings Are Gateway To Digitalization and IIoT (Part 1)

In a recent presentation at this year’s Hannover Fair in Germany, Stefan Spindler, CEO of the Industrial Group at Schaeffler AG outlined the company’s vision for the future. Schaeffler has one of the broadest ranges of rolling bearings and power-transmission products in the industry, offers extensive engineering expertise for its customers and strives for the highest possible quality, efficiency and delivery performance, he said

In addition, noted Spindler, the company views Industry 4.0 and digitalization as key opportunities going forward. He spoke in detail about Schaeffler’s Smart EcoSystem, a digital infrastructure for integrating sensor-equipped components into cloud-based systems and specific business models based on digital service—and how it all ultimately benefits the user.

Smart EcoSystem is a comprehensive, cloud-based hardware and software infrastructure that takes into account every stage of digital added value—from components equipped with sensors through to digital services like tracking machine performance and predictive maintenance, he explained.

Components like rolling bearings equipped with sensors are the fundamental “enablers” for these digital services. Schaeffler’s aim is to continuously transform conventional mechanical products and integrate them into the digital world. While bearings and guidance systems equipped with sensors have been on the market for several years, Schaeffler has expanded such capabilities with the new FAG VarioSense rolling-bearing system—one key component of the Smart EcoSystem. It is based on standard products and can be configured in a modular fashion with several different sensors, which allows virtually every desired parameter to be monitored and permits easy access to digitalization and the Internet of Things.

FAG VarioSense bearings integrate several sensor elements into a ring-shaped housing with a section height of only 7 mm. The sensor cluster occupies approximately the same space as a rotary shaft seal, said company officials. For simple handling, the sensor housing is fixed to the outer ring and the sensor ring is fixed to the bearing inner ring, resulting in a compact overall unit.

Customers can set the number and combination of measured values for a specific application. Sensing parameters include:

• Temperature from -40° to 125°C.

• Speed up to 17,000 rpm.

• Rotation direction.

• Number of revolutions or position with 56 to 96 impulses/revolutions (depending on size).

• Vibration signals for long-term trending.

• Maximum radial shaft displacement to a resolution of 1 µm.

The original article can be found here

Darbar Company is one of the leading suppliers of Power Transmission Products. Consumers in Pakistan looking for bearing products can contact us here

Avoiding Bearings "Made in Wherever"

You can always tell when times are good in the automotive market due to the flurry of acquisitions, mergers and divestitures. As we are coming off a record 2016 in vehicle sales, many companies are flush with cash burning a hole in their billion-dollar pockets. There isn’t enough front-page space for the number of companies reporting record profits for 2016. Others, however, realize that if they didn’t see black in 2015-16, the writing is on the wall and it is likely time to start looking for a willing buyer ready to spend some new money on a discounted, struggling company.

As they say around here, “If you can’t beat ‘em, buy ‘em.”

In Detroit we saw some huge, industry-changing acquisitions, with AAM buying Metaldyne; Dana buying part of USM; and FCA looking for a buyer while GM is in THE process of dumping Opel. Many companies are doubling down on domestic manufacturing; meanwhile, Chinese companies continue to aggressively invest in U.S. markets.

All of this churn in the marketplace can make it tricky to differentiate the real competition from dotted line allies. As we deal with the Big 6 global bearing companies — Timken, SKF, NTN, NSK, JTEKT, Schaeffler — and an ever-increasing powerhouse — Nachi, along with the emerging Chinese behemoths ZWZ, LYC, HRB, TMB, Wanxiang, C&U and CW — you may be frequently left with the question of who exactly is doing what. Out of the thousands and thousands of bearing companies, (someone told me there were around 9,000 bearing companies in Ningbo China alone) only a small fraction is actually producing bearings. Indeed, the companies mentioned above produce well over 90% of the world’s bearings. Of course, many, many smaller bearing companies do produce their own products. In global terms however, those numbers make up a very small part of the market. Supporting this ~ $70 billion roller bearing marketplace are what I would call assemblers, partial manufacturers, resellers, re-branders and distributors.

Now, more than ever before, it is common for bearing companies to purchase components that are in the least bit unfavorable to the bottom line. In this incredibly competitive marketplace the public companies need to show profitability to keep the stock price stable. This often means that if they are faced with the option of producing a custom ring at a single digit or flat rate of return, they are likely to shop out the business to another manufacturer. These deals are usually kept very close to the vest for obvious reasons, a major one being that if you spent tens of millions of dollars in marketing to tell people that your product is the best, people expect it to be your product.

The point I am making is the need to hold your suppliers accountable. Often a large supplier will not tell you whom they are buying your components from, but you absolutely have the right to know where your parts are being manufactured. If you are paying top dollar for what you believe to be top quality steel from a top quality producer, you don’t need to be shy about asking questions. If you can’t get a plant tour of where your bearings are being manufactured, there is a good chance it is because they are buying it somewhere else. If they are buying cheaper offshore rings — and then finishing them in a high-priced manufacturing country so that they can stamp them with “Made in Wherever” — you have some work to do, my friend.

The original article can be found on: PowerTransmissions Blog

Darbar Company is one of Pakistan's leading distributor of various types of bearings. Check out our home page to see which brands of bearings we carry

The Ultimate Guide to Full Ceramic Bearings In Water Processing, Water Filtration and Liquid Handling (Part 2)

Generally speaking, ceramic materials are extremely durable. Most of them are man-made using chemical processes, and consequently can withstand extremely high temperatures and corrosive materials.

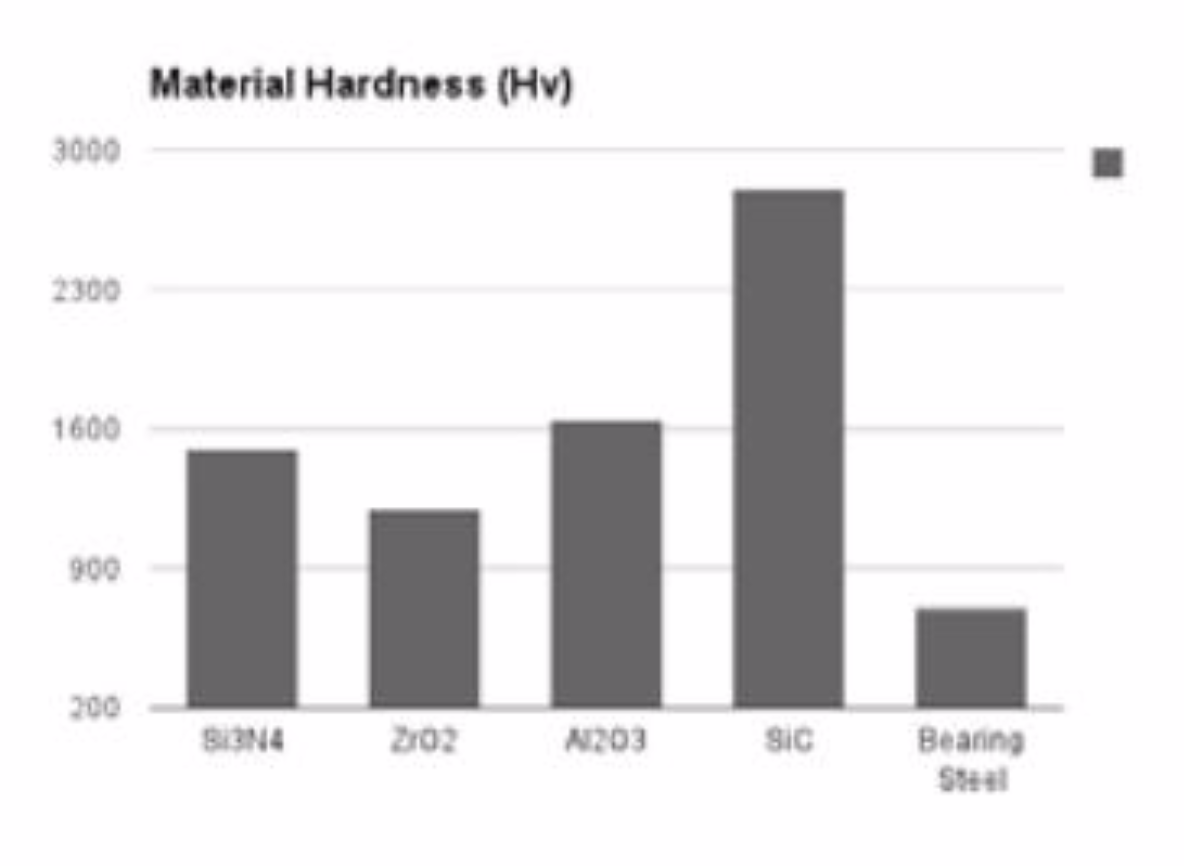

Full ceramic bearings have a much longer lifespan than hybrid ceramic bearings or the steel alternatives, particularly when they aren’t placed under a considerable load. This can be attributed to many properties of full ceramic bearings. Firstly, ceramics are much stronger. As a result, the balls or races of the bearing do not become distorted when placed under load. However, the superiority of full ceramic material increases with the load, and full ceramic materials are still at risk of premature failure in these cases.

The main limitation of ceramic bearings if the fact they can be quite brittle. Consequently, you must analyze the load to ensure the chose material can cope with the stress. Zirconia Oxide will handle large loads better than the rest of the full ceramic materials.

Ensuring Extensive Lifespan of Bearings

Generally speaking, ceramic materials are extremely durable. Most of them are man-made using chemical processes, and consequently can withstand extremely high temperatures and corrosive materials.

Full ceramic bearings have a much longer lifespan than hybrid ceramic bearings or the steel alternatives, particularly when they aren’t placed under a considerable load. This can be attributed to many properties of full ceramic bearings. Firstly, ceramics are much stronger. As a result, the balls or races of the bearing do not become distorted when placed under load. However, the superiority of full ceramic material increases with the load, and full ceramic materials are still at risk of premature failure in these cases.

The main limitation of ceramic bearings if the fact they can be quite brittle. Consequently, you must analyze the load to ensure the chose material can cope with the stress. Zirconia Oxide will handle large loads better than the rest of the full ceramic materials.

Electrical Insulation With Ceramic Bearings

The ceramic bearings are also non-magnetic, and with the exception of Silicon Carbide, provide good electrical insulation. Silicon Nitride offers the best electrical resistance, but is closely followed by Zirconia Oxide, which is readily available and fits within most budgets.

Improved Performance of Bearings in Water and Other Liquids

Research has demonstrated that full ceramic bearings perform better than any alternatives when placed in water. Depending upon the material used, the lifespan can be up to 70 times longer than stainless steel bearings, a common alternative. The best ceramic materials for use in water processing environments are Silicon Nitride and Zirconia Oxide. Hybrid ceramic bearings also perform better than steel, but their lifespans are significantly shorter than full ceramic materials, which in some cases have a lifespan 5 times longer.

Resistance to Corrosion

It is not feasible to use metallic bearings within industries handling water or other liquids, as they will corrode rapidly. When selecting the most appropriate material for the ceramic bearings, you should also consider the types of liquids the bearings will encounter. If the bearings will be used in environments containing corrosive materials, the lifespan will be significantly altered. Silicon Nitride offers good resistance to the majority of chemicals, so is often a good choice when the budget permits.

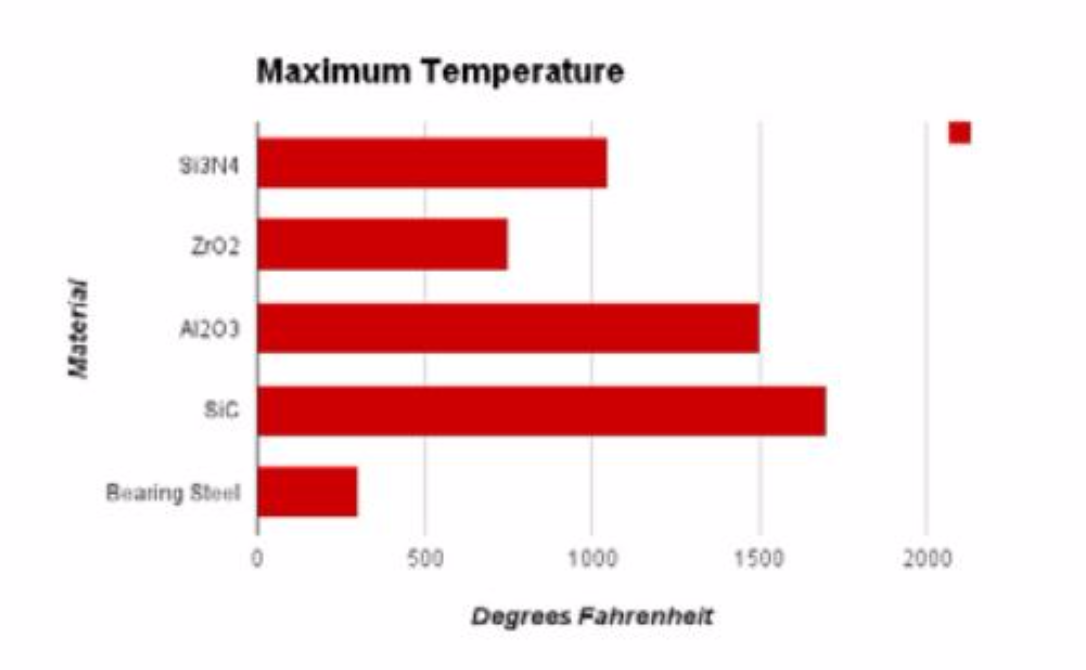

Temperature Considerations

When deciding which material to use, it’s important to consider the technical properties of each material to evaluate their suitability. One of the most important aspects to consider, particularly when working with liquids that may reach high temperatures, is the temperature of the environment in which you will be using the bearings. Silicon Nitride can be used in environments reaching up to 1050.F, without loading. However, this can change significantly when used in industries handling liquids, as the bearings can encounter significant loading.

The coefficient of thermal expansion is possibly a more useful characteristics, as it provides you with an indication of the materials ability to cope in response to heating and cooling. Full ceramic bearings offer relatively low coefficients, compared to the non-ceramic alternatives. For example, Silicon Nitride has a coefficient of 3.2 x 10-6/k and Silicon Carbide offers 3 x 10-6/k. Zirconia Oxide and Aluminum Oxide are considerably higher, at 10.5 x 10-6/k and 8.5 x 10-6/k respectively, but both of these are much lower than bearing steel, which has a coefficient of 12.5 x 10-6/k. In environments with considerable temperature changes. Silicon Nitride and Silicon Carbide are the best choices. These materials also offer good thermal shock resistance (up to 1112.F in Silicon Nitride, and 752.F in Silicon Carbide), which indicates minimal risk of fracture due to the changing temperatures.

Resistance To Fracture Under Load

The material’s ability to resist fracture is essential when used with liquids, such as water processing, as pressure is increased when submerged. Therefore, another characteristic that must be considered is fracture toughness. This indicates how capable the material is at resisting fractures in high-pressure environments. Zirconia Oxide offers the best resistance, with a fracture toughness of 10 MPA*m1/2, closely followed by Silicon Nitride at 6.2 MPA*m1/2. These are consequently the best materials to use in a high-pressure environment, where the risk of cracks and fractures is high.

The development of mechanical equipment for use in wet environments is no easy task, and selecting the right materials is vital to ensure the success of your business. Mistakes can be expensive, so it’s important to understand the properties of the available resources. When it comes to bearings, metallic or hybrid options are simply not an option if significant contact with water is expected. Instead, full ceramic materials should be used to ensure the machinery will be built to last, and will operate efficiently for the duration of its use.

The Ultimate Guide to Full Ceramic Bearings In Water Processing, Water Filtration and Liquid Handling (Part 1)

Bearings are essential mechanical components of machinery used in a variety of industries. A bearing’s purpose is to help facilitate desired motion, limit undesired movement, and reduce friction. Bearings are thought to date back as far as the ancient Egyptian era, when wooden bearings were used to assist with the movement of heavy objects. Since then, the concept has developed considerably; bearings now come in a variety of forms, and are made from many different types of materials.

Bearings are an essential component in the majority of mechanical designs and equipment. It is important to consider the most effective materials when designing industrial machinery, especially in applications where water, or other liquids are present. Many materials will be unable to overcome the challenges associated with operating in a wet or corrosive environment.

To overcome the challenges faced by industries involved in water processing, water filtration and liquid handling, full ceramic bearings should be used. This paper will outline the properties of full ceramic bearings, and enable you to determine whether they are the most appropriate type for your mechanical processes.

Bearings are essential mechanical components of machinery used in a variety of industries. A bearing’s purpose is to help facilitate desired motion, limit undesired movement, and reduce friction. Bearings are thought to date back as far as the ancient Egyptian era, when wooden bearings were used to assist with the movement of heavy objects. Since then, the concept has developed considerably; bearings now come in a variety of forms, and are made from many different types of materials.

Bearings are an essential component in the majority of mechanical designs and equipment. It is important to consider the most effective materials when designing industrial machinery, especially in applications where water, or other liquids are present. Many materials will be unable to overcome the challenges associated with operating in a wet or corrosive environment.

To overcome the challenges faced by industries involved in water processing, water filtration and liquid handling, full ceramic bearings should be used. This paper will outline the properties of full ceramic bearings, and enable you to determine whether they are the most appropriate type for your mechanical processes.

Comparing Full Ceramic Materials’ Properties

There are a number of ceramic materials that can be used to produce full ceramic bearings. While these share a number of properties, they also offer distinct characteristics, which will help you to determine the most suitable material for your machinery. Here’s a guide to the most common materials used to produce full ceramic bearings:

Zirconia Oxide (ZrO2)

Zirconia Oxide was first used in the 1960s. It was used in space travel, creating a thermal barrier to enable space shuttles to enter the Earth’s atmosphere. It copes well with high temperatures, but doesn’t handle thermal shock resistance to the same extent as alternative ceramic materials, such as Silicon nitride. It’s best used in high temperature environments that involve minimal loads. It’s highly resistant to corrosion, which makes Zirconia Oxide the perfect choice for use with highly corrosive liquids. It’s an incredibly strong material, which also makes it ideal for use in mechanical applications involving fracture risk. ZrO2 has an operating temperature range of -85.C to 400.C

Silicon Nitride (Si3N4)

Silicon Nitride is a ceramic material produced using a series of chemical reactions, creating a full ceramic material with distinctive properties. The material is dark in color, and is one of the most superior types of ceramic material in terms of quality and durability. This material is relatively expensive, but the extra cost is worthwhile if you’re looking for something that can withstand high temperatures and harsh mechanical conditions. In terms of withstanding high temperatures, silicon nitride is superior to alternative metallic solutions, and it has a lower thermal expansion coefficient than many alternative ceramic materials. This makes it an excellent choice when thermal shock resistance is a high priority. Si3N4 has an operating temperature range of -100.C to 900.C

Aluminum Oxide (Al203)

Aluminum Oxide is the most popular ceramic ball material, and its common uses expand far beyond the reams of ceramic bearings. It’s produced through the process of calcination of aluminum hydroxide, which creates a durable and highly resistance ceramic material. This material is best known for its high compression strength, and its ability to resist corrosion when faced with a variety of abrasive chemicals, even when the environment involves extremely high temperatures. Less expensive than some of the alternative ceramic materials, aluminum oxide is readily available and is the most popular choice ceramic bearing for projects in which the available budgets are limited.

Silicon Carbide (SiC)

Silicon Carbide is produced by chemically combining carbon and silicon atoms. It has excellent mechanic properties, which makes it a fantastic choice for use in the creation of bearings. Grains of silicon carbide have been used for many years as an abrasive, most commonly in the form of sandpaper. However, these grains can be combined through sintering to create the highly durable ceramic material used to create silicon carbide bearings. This is a strong, durable ceramic material with a low density, low rate of thermal expansion, and fantastic thermal shock resistance, making it suitable for use in a wide variety of applications.