Avoiding Bearings "Made in Wherever"

You can always tell when times are good in the automotive market due to the flurry of acquisitions, mergers and divestitures. As we are coming off a record 2016 in vehicle sales, many companies are flush with cash burning a hole in their billion-dollar pockets. There isn’t enough front-page space for the number of companies reporting record profits for 2016. Others, however, realize that if they didn’t see black in 2015-16, the writing is on the wall and it is likely time to start looking for a willing buyer ready to spend some new money on a discounted, struggling company.

As they say around here, “If you can’t beat ‘em, buy ‘em.”

In Detroit we saw some huge, industry-changing acquisitions, with AAM buying Metaldyne; Dana buying part of USM; and FCA looking for a buyer while GM is in THE process of dumping Opel. Many companies are doubling down on domestic manufacturing; meanwhile, Chinese companies continue to aggressively invest in U.S. markets.

All of this churn in the marketplace can make it tricky to differentiate the real competition from dotted line allies. As we deal with the Big 6 global bearing companies — Timken, SKF, NTN, NSK, JTEKT, Schaeffler — and an ever-increasing powerhouse — Nachi, along with the emerging Chinese behemoths ZWZ, LYC, HRB, TMB, Wanxiang, C&U and CW — you may be frequently left with the question of who exactly is doing what. Out of the thousands and thousands of bearing companies, (someone told me there were around 9,000 bearing companies in Ningbo China alone) only a small fraction is actually producing bearings. Indeed, the companies mentioned above produce well over 90% of the world’s bearings. Of course, many, many smaller bearing companies do produce their own products. In global terms however, those numbers make up a very small part of the market. Supporting this ~ $70 billion roller bearing marketplace are what I would call assemblers, partial manufacturers, resellers, re-branders and distributors.

Now, more than ever before, it is common for bearing companies to purchase components that are in the least bit unfavorable to the bottom line. In this incredibly competitive marketplace the public companies need to show profitability to keep the stock price stable. This often means that if they are faced with the option of producing a custom ring at a single digit or flat rate of return, they are likely to shop out the business to another manufacturer. These deals are usually kept very close to the vest for obvious reasons, a major one being that if you spent tens of millions of dollars in marketing to tell people that your product is the best, people expect it to be your product.

The point I am making is the need to hold your suppliers accountable. Often a large supplier will not tell you whom they are buying your components from, but you absolutely have the right to know where your parts are being manufactured. If you are paying top dollar for what you believe to be top quality steel from a top quality producer, you don’t need to be shy about asking questions. If you can’t get a plant tour of where your bearings are being manufactured, there is a good chance it is because they are buying it somewhere else. If they are buying cheaper offshore rings — and then finishing them in a high-priced manufacturing country so that they can stamp them with “Made in Wherever” — you have some work to do, my friend.

The original article can be found on: PowerTransmissions Blog

Darbar Company is one of Pakistan's leading distributor of various types of bearings. Check out our home page to see which brands of bearings we carry

Do’s and don’t of cam follower installation

If you have cam follower bearings installed in your facility, then maintaining a great performance from those bearings will be something you are interested in. You can help obtain great bearing performance if you keep some particulars in mind during installation.

If you have cam follower bearings installed in your facility, then maintaining a great performance from those bearings will be something you are interested in. You can help obtain great bearing performance if you keep some particulars in mind during installation.

DO

1. Do install the oil hole plug in applications where the bearing will not be re-lubricated. Because it’s an optional part of the installation, in applications where re-lubrication will be performed, the user may be inclined to discard the oil hole plug. Installing the plug helps protect the bearing from contaminant entry, such as fine grit, metal dust, or liquids, promoting longer life. Longer life means less down time and fewer bearing replacements.

2. Using a press fit on the stud helps to create proper support of the stud in application; it can be used when installing stud-type cam followers. Press fitting is when you have an interference fit requiring you to apply pressure on the stud end face of the bearing. Be sure to apply the pressure through the stud end face, preferably using an arbor press.

3. Specifically, for the yoke type bearings: please do back up the bearing’s end plates. Yoke type bearings require a housing to support the end plates. Do not shirk on keeping the end plates supported. Keeping those end plates supported maintains the bearing’s proper assembly in operation, and helps avoid premature application breakdown and possible injury due to disassembly. It will also prevent unnecessary bearing replacement and unnecessary cost.

4. You may know the stud type cam followers require a certain amount of torque applied to the locking nuts, in order to adequately lock the stud in place. Overtorque can cause bearing damage and undertorque can allow bearing disassembly. Excessive torque can result in stud elongation or fracture. Inadequate torque can allow the cam follower to become disassembled from the housing. Keeping the proper torque as shown in the bearing’s chart will maintain clamping pressure adequate to lock the stud in place, keeping the bearing in its intended position.

5. Some applications need little maintenance, such as those involving slower speeds, fairly clean environments and ambient temperatures. However, re-lubrication becomes more crucial as application speed, temperature, or contamination levels increase. Do regularly inspect and as necessary re-lubricate your bearings. Keeping your bearings in top condition maximizes their operational performance and life. Regular check-ins are also a good opportunity to inspect the state of their installation and working environment.

DO NOT

1. During installation, do not hammer directly on the bearing! Doing this can cause damage to your bearing or injury to those involved.

2. Don’t neglect your bearings. I don’t need to tell you that negligence can result in permanent damage and shorten operating life. In short, you’re wasting money.

Darbar Company is Pakistan's leading supplier in Cam Followers. You can send your particular inquiries by filling out this form

Original article can be found in the February issue of Bearing-News Magazine

Bearing Research: Going To The Atomic Scale

This article provides insight into the four main lines of research through modelling at SKF: bearing steel, fatigue mechanisms, polymer design and tribology.

In the past few years SKF has been expanding its knowledge with the atomic scale simulation methods such as DFT, MD, and DPD, to understand how materials behave in its products. This has enabled and will continue to enable SKF to innovate and cope with ever-increasing technological challenges by ensuring that every atom is in the place it belongs.

This article provides insight into the four main lines of research through modelling at SKF: bearing steel, fatigue mechanisms, polymer design and tribology.

In the past few years SKF has been expanding its knowledge with the atomic scale simulation methods such as DFT, MD, and DPD, to understand how materials behave in its products. This has enabled and will continue to enable SKF to innovate and cope with ever-increasing technological challenges by ensuring that every atom is in the place it belongs.

Technology

Imagine if one could become so small that he or she could dive into solid materials and see the structure of the atoms – how the interact, move and respond when external force is applied and how the external temperature influences their properties and changes their structure. If this were possible one could better select, process and design the materials used to manufacture products and machines.

At the SKF Engineering and Research Centre (ERC) in the Netherlands, research is done with the objective of virtually diving into the materials that make up SKF’s products to achieve a better understand of their behavior. This enables SKF to respond to requests from customers, and more importantly, to develop new materials for its products that increase their quality, durability and other specific properties.

In most of the cases, the use of experimental methods is enough to gain sufficient understanding of how external constraints might affect the materials from which products are made and to find preventive and counteractive solutions.

Nevertheless, even with the use of state-of-the-art experimental techniques, it is simply not always possible to get sufficient understanding of the effect that certain phenomena can have on the materials. In addition, in some cases such as with a new material or product that in the design phase, being limited to the use of laboratory test tools is not always time-efficient or cost-effective. This is why computational methods are essential

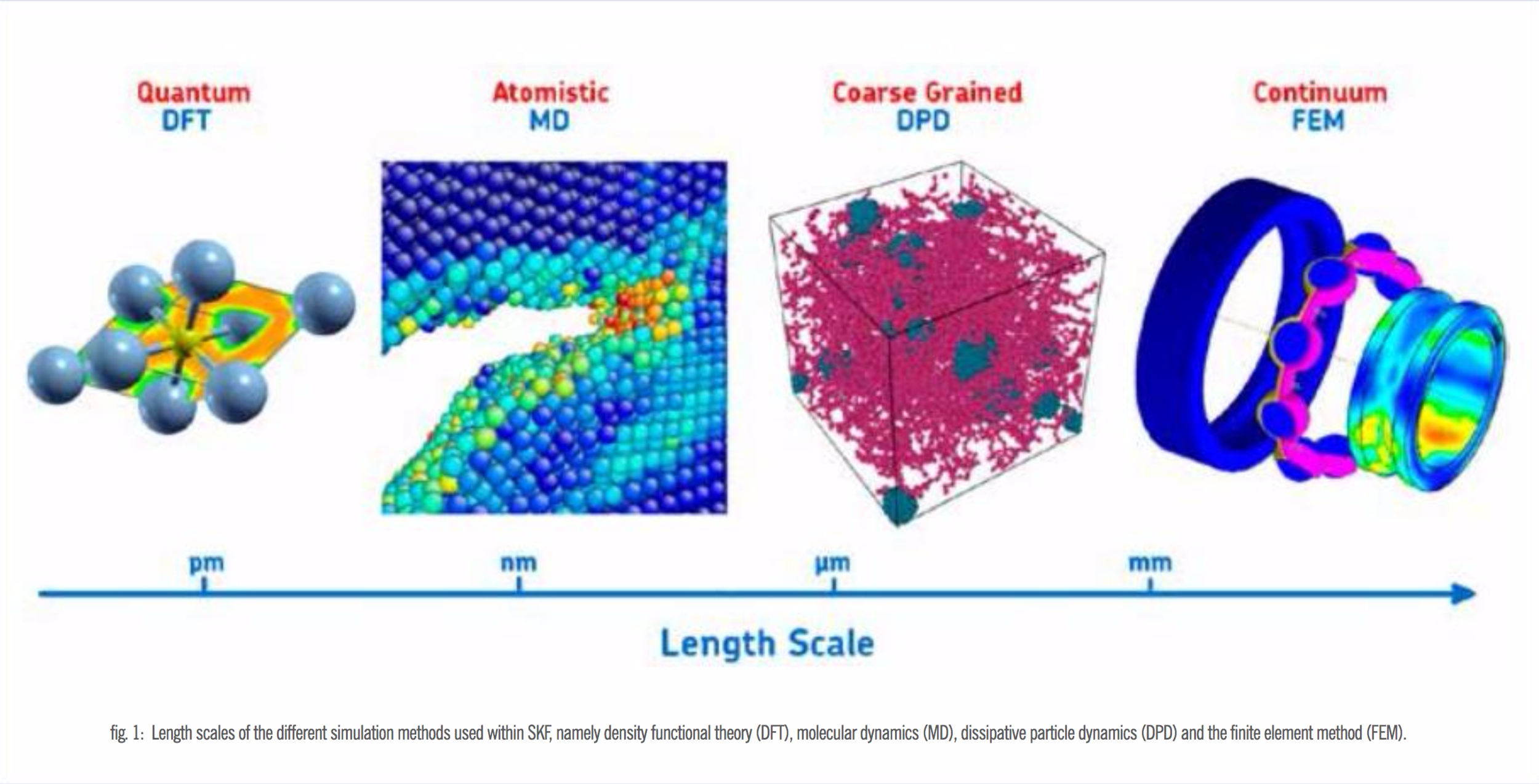

When it comes to mechanical parts, e.g., rolling bearings, most design issues can be worked out using “large scale” simulation techniques, such as the widely used finite element method (FEM). However, some special issues go beyond the capabilities of this modelling tool and require being treated with alternative mesoscopic and microscopic simulation methods.

To get a thorough understanding of SKF’s products and be able to tackle the issues that might have an origin at particular time and length scales, scientists at SKF are constantly developing their know-how in the use and advancement of multi-scale simulation methods. This means that there are different tools (imagine magnifying glasses, all with a different magnifying power) that can be used to understand specific phenomena that determine the behavior of a material in application conditions. This is why the models that are applied at SKF range from quantum mechanical to continuum (fig.1).

The deeper one dives inside the material, the more calculation power and time are needed to make simulations. For this reasons, a high-performance computer cluster with 1,536 processors is being used in SKF facilities.

Currently, there are four major lines of research for which meso- and micro-scale methods are used.

Steel Design

The first line of research is part of the project “MultiHy”, short for Multiscale Modeling of Hydrogen Embrittlement. This project is led by a consortium formed by various European industrial and academic partners and is funded by the European Union. The initial motivation for this project is that there is ample experimental evidence that supports the idea that hydrogen decreases the fatigue life of bearings and structural steels. This effect of hydrogen is known within the technical jargon as hydrogen embrittlement. SKF’s main interest is MultiHy is to be able to predict how hydrogen diffuses into and through bearing steels and, more importantly, to discover how available hydrogen can be trapped and immobilized to neutralize the impact of hydrogen embrittlement on bearing service life.

Such simulations on hydrogen mobility and its effect on fatigue life complement other ongoing research dealing with various sources of hydrogen, e.g., humid environments and possible degradation of lubricants.

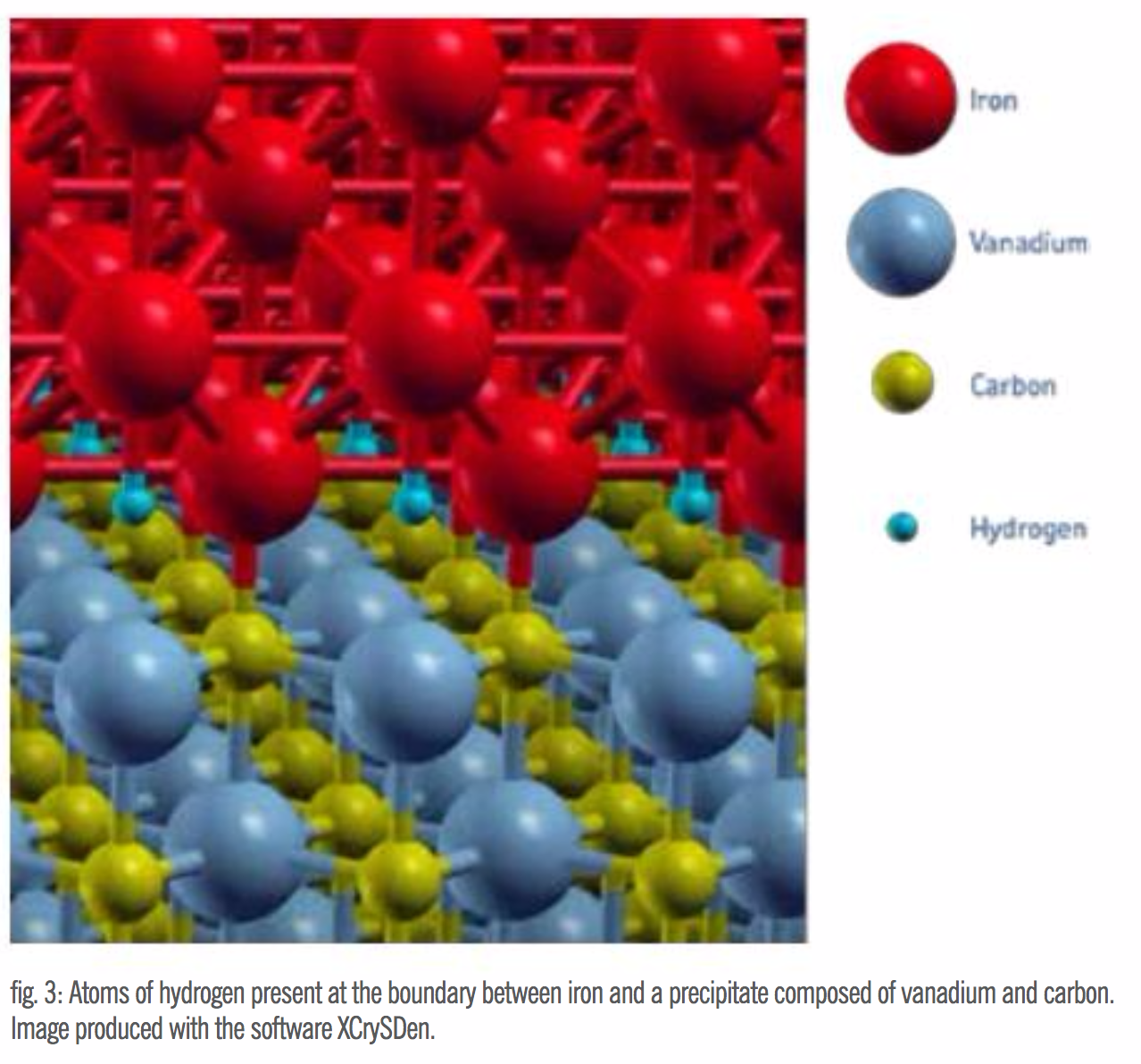

From the atomistic point of view, simulations are being carried out using a computational quantum mechanical modelling method called density functional theory (DFT), which is commonly used to investigate the electronic structure of many-body systems (fig.2). More specifically, simulations are being done to evaluate the mechanical properties and the influence of hydrogen in a new experimental vanadium-containing bearing steel (fig.3) in which hydrogen can be trapped to avoid embrittlement. The results of the MultiHy project can help with the final development of this new steel, so that it can be eventually considered for applications where hydrogen resistance is needed.

Fatigue Mechanisms

The second line of research is aimed at the atomic description of the microstructure of bearing steels and its influence on the behavior of the material when subjected to rolling contact fatigue. For this project, the molecular dynamics (MD) method is being used to study how the atoms move and interact with each other when a crack is initiating and propagating through bearing steel (fig.4). The understanding of this phenomenon will enable SKF to find ways to increase the life and overall performance of SKF products.

Polymer Design

The third application deals with the study of filled rubber materials used in the manufacturing of seals. The overall goal is to identify and quantify the physical phenomena taking place at different scales that influence the quasi-static and dynamic stress-strain behavior of filled rubber. This project is being carried out by SKF in collaboration with scientists from Tsinghua University in China and from the University of Barcelona in Spain.

Dissipative particle dynamics (DPD), a meso-scale simulation tool that enables analysis of the dynamic properties of fluids and polymers (fig.5) at scales that go beyond those that can be treated using MD, is used here. By employing DPD, the effect of various factors, such as the interaction between filler particles and polymer chains and the topological changes in the polymer network in the static and dynamic mechanical behavior of sealing materials, can be fully considered.

Tribology

The final application addresses the lubricated contact between two surfaces, such as that between a rolling element and a raceway in a hybrid bearing. The method used for this work is also MD. The goal is to explain the fundamental differences in friction and wear between steel/steel and steel/ceramic surfaces to improve the performance of hybrid bearings. Also, chemical reactions between the lubricant and the surfaces can be considered.

So far, the modeling has revealed that there are fundamental differences between steel/steel and hybrid contacts related to friction and wear. More importantly, the results have shown that hybrid contacts present lower friction than steel/steel contacts.

This article has been extracted from the latest edition of Bearing-News magazine

Three more bearing killers and how to stop them: Part 2

Bearing failure can grind your operations to a halt, resulting in significant lost time and production. Here are the last three of our six common factors that can cause bearings to fail, and what you can do to prevent them.

Bearing failure can grind your operations to a halt, resulting in significant lost time and production. Here are the last three of our six common factors that can cause bearings to fail, and what you can do to prevent them.

#4: Contamination. Even the tiniest of foreign particles can interfere with the lubrication that enables a bearing to function as intended. There are a number of contamination sources, depending on the application. Shop dust, sand, fine metal particles from nearby machining, water and dirt can all interfere with the lubricant that keeps a bearing operating, and can damage the bearing itself. Particles rolling through the bearings and rolling elements will cause premature damage, increasing stress and shortening overall bearing life.

The best protection against contamination is a proper seal, which must be matched with the given application to offer the best possible performance. This information should be available through the bearing manufacturer. Generally, seals should be regularly checked for hardening and cracking around the radial lip; they should be replaced as soon as possible if any visible damage is detected.

Contamination can occur at other points in the bearing lifecycle. Technicians should routinely test oil and grease samples for solid particles. Additionally, when bearings are removed for inspection, technicians should make sure to wash, dry and then coat bearings with the appropriate preservative before packing away, using the proper storage techniques.

#5: Overloading. Bearings are designed and engineered to operate at specified loads, and when pushed beyond those limits, trouble can occur. Overloaded bearings can fracture components, and left unchecked can lead to more serious damage or consequences.

Like overheating, warning signs of overloaded bearings should be monitored constantly. Abnormal noises and vibrations, overheating, the presence of metallic chips in lubricant filters, and overall diminished performance of the bearing can all indicate that a bearing is operating beyond its load limits. The higher the overload, the greater the damage. Other indications include the fatigue, pitting or flaking away of bearing materials, roller fracture, peeling, and potential plastic deformation or subsurface fracture of the rolling elements or raceways.

#6: Corrosion. Bearing applications in harsher industrial environments are more susceptible to corrosive damage caused by rogue fluids or corrosive atmospheres that can interfere with the protective lubricant. Corrosion can lead to wear, which can, in turn, lead to bearing failure

Like overloading, subpar performance due to corrosion can often be detected by increased vibration and noise during operation. Corrosion can be identified by reddish and brown discoloration found on the bearings and raceways—not to be confused with the discoloration caused by overheating. Ensuring the use of proper seals and that those seals are not damaged, is one of the best ways to prevent corrosion on the bearing and raceways. External seals can also be used in more extreme environments if necessary.

Thorough documentation of your bearing installation and maintenance processes can help ensure technicians are being diligent in their monitoring of these common causes of bearing failure. Recordkeeping can help identify trends in bearing performance, forecasted maintenance, and the length of service intervals. Include date, equipment model and serial numbers, bearing assembly and serial number, and the bearing’s manufacturer in your documentation.

In many cases, bearing damage can progress over time. Periodic or continuous condition monitoring (vibration, temperature, lubricant sampling, etc.) can aid equipment and process operators define trends over a bearing lifecycle. Establishing specific operating limits can help define the most appropriate interval for bearing replacement.

Armed with this information, more informed decisions can be made to ensure operations keep your business running smoothly, efficiently and profitably.

Darbar Company is Pakistan's leading wholesale distributor in Power Transmission products. Darbr Company carries over a million types of bearing ranging from Needle, Ball and etc. You can send your specific inquiries by filling out this form

Check out the other three reasons here

Read the original article at BearingTips: http://bit.ly/2lIiyHR

3 Bearing Killers and How To Stop Them: Part 1

Bearing failure can grind your operations to a halt, resulting in significant lost time and production. Here are the first three of six common factors that can cause bearings to fail, and what you can do to prevent them.

Bearing failure can grind your operations to a halt, resulting in significant lost time and production. Here are the first three of six common factors that can cause bearings to fail, and what you can do to prevent them.

No matter the application, the proper functionality of bearings is essential to optimize operations. Whether a bearing is a cylindrical, spherical, ball or roller bearing, its precise design and engineering require special attention to ensure it’s working correctly. Bearing failure means downtime, maintenance and a major blow to operational efficiency—and in many cases, that failure can be easily prevented.

Applications requiring dependable bearing operation are countless but common reasons for bearing failure are fairly narrow. Though improvements in technology, design and user training have helped reduce failure incidents, understanding how and why bearings commonly fail is critical.

Here are the first three of six common reasons for bearing failure and how to make sure they don’t bring operations to a halt:

#1: Improper Handling and Installation. Proper bearing care begins when the bearing first arrives at the application site. From the shipping dock, to storage, to installation, proper handling and care is necessary to ensure the bearing will function as intended.

Even the smallest imperfections can shorten a bearing’s lifespan, and many nicks and scratches occur before the bearing is even put into use. Damage can occur when a bearing is in storage; therefore, if stocking bearings prior to needing them on your plant or shop floor, make sure the proper storage techniques are being followed. Don’t remove the bearing from the manufacturer’s original packaging unless absolutely necessary; if it must be removed, store in anticorrosive wrapping, and apply the appropriate preservatives to the bearing first.

When ready to install, cleanliness is critical. Technicians should perform the work in as clean an environment as possible, using clean tools, and should take care not to remove any of the preservative coating. Carelessness is the most common cause of damage to the bearing throughout the installation process. Poor handling while removing the outer races from housings or wheel hubs, for instance, can leave burrs or high spots in outer race seats. Tools can inadvertently gouge housing seats, leaving imperfections that can increase rolling contact stress, limit fatigue life or fracture machine components in the worst cases—all the more reason to ensure your installation processes are conducted with care and precision.

#2: Improper Lubrication. Lubrication is the lifeblood of proper bearing operation, and it is dependent on several variables in any given application.

Most bearing manufacturers and suppliers will recommend a specific lubricant type, grade, supply system, viscosity and additives for the application. They will also provide the amounts of lubricant that should be used and how often it should be changed or replenished. More application-specific recommendations and details including loading, speeds and sealing are often included as well.

Just like the bearings themselves, lubricants must be stored properly. Shelf life, temperature, filtration and other precautions will again be available via your bearing/lubricant supplier.

Technicians should adhere closely to these recommendations—bearing compatibility and performance depend on it. Underfilling and overfilling, mixing and matching lubricants, and changing lubrication at irregular intervals can all result in significant damage that can bring your operations to a standstill.

#3: Overheating. A primary function of proper lubrication is to prevent the overheating of bearings and associated components. Overheating can lead to damage and ultimately breakdown for a variety of reasons related to the lubricant. Higher temperatures can be caused by ambient temperatures, process temperatures, and severe operating conditions that can increase rolling contact friction. Likewise, lower ambient temperatures can have a negative effect—lubricant viscosity increases at lower temperatures and can cause improper flow and therefore compromise protective benefits. Your lubricant supplier can provide the ideal operating temperature change.

Technicians can and should do more than simply follow supplier instructions to ensure lubricants are performing properly and keeping their bearings at the appropriate temperatures. Be vigilant about monitoring bearings for heat-related trouble signs that can impact lubrication and ultimately the bearing itself. In order of severity, these symptoms include:

- Bearing discoloration. This will occur as a result of metal-to-metal contact, a sure sign of a lubrication issue. Look for gold and blue discoloration on races and rollers; lubricant staining is common in mild cases, while the metal itself may be discolored by excessive heat in worse cases.

- Peeling and scoring. Marks cut into the metal or peeling metal indicate a more severe lubrication/heat issue and should be addressed immediately.

- Localized scoring. This occurs due to the breakdown of the lubricating film which causes direct contact between components. Address immediately.

- Cumulative wear. High localized heat can alter the geometry of the bearing itself, resulting in a locked-up bearing that can cause significant additional damage.

Read the original article at: http://bit.ly/2m8jZgo

Follow bearing tips to get the latest tips on bearings