How To Prevent Pulley Slippage

There are a variety of methods used to attach pulleys to shafts. Knowing the advantages and disadvantages of each one will help you make a better choice when installing drive components into your assembly. Using the appropriate method for your application can go a long way in preventing damage and possible equipment failure. Consideration should also be given to field service needs.

There are a variety of methods used to attach pulleys to shafts. Knowing the advantages and disadvantages of each one will help you make a better choice when installing drive components into your assembly. Using the appropriate method for your application can go a long way in preventing damage and possible equipment failure. Consideration should also be given to field service needs.

Controlled tolerances between the shaft and pulley prevent slipping and can be achieved through various mounting devices or fastening methods. Type of connections between shaft and pulley:

- Set-screw

- Fairloc

- Press-fit

- Shaft-lock

- Shaft extenders

- Clamp

Structure: advantages and disadvantages of each:

Set-screw type connection is a simple, in expensive way to connect a pulley to a shaft. The pulley requires an additional extension (Hub) on which, perpendicular to the direction of the shaft a hole or holes are drilled and tapped.

Drilling and tapping can be performed on any type of material the pulley is made of, most common are aluminum, stainless steel, steel, and plastics, with a metal or reinforced hub.

Disadvantages: require additional axial space because of the hub's projection; torque transmission is limited in comparison to press-fit and shaft lock types. In addition, different types of set screw tips can damage the surface of the shaft.

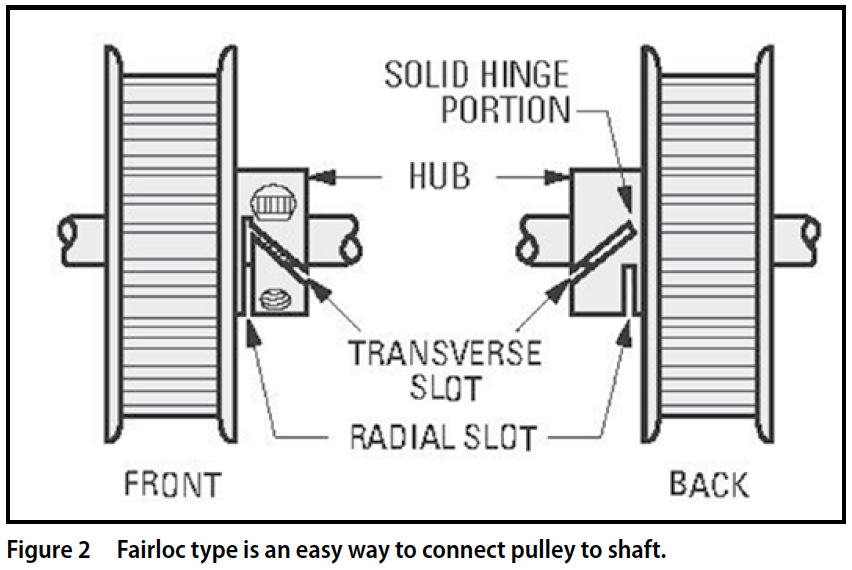

Fairloc Type is an easy way to connect the pulley to the shaft.

Two slots are machined into the hub - one oriented radially, the other angularly - to create a transverse wedge which remains attached to the solid portion of the hub on one side. The resultant cantilevered clamping section has a tapped hole to accept a cap screw which passes through a clearance hole in the solid portion of the hub, and into a threaded hole in the transverse wedge section. As the screw is tightened, the cantilevered section clamps the shaft securely.

The compact, self-contained design reduces misalignment and can be tightened and released repeatedly without marring the shaft. Produced in stainless steel, aluminum and brass, it is well suited for applications that require moderate torque and speed. For optimal performance Fairloc hubs require controlled tolerances between the shaft and pulley (suggested clearance fit .0001"/.0008"). For high-torque/high-speed applications, shaft locks are a better option.

Press-fit type, especially for metal on metal, is a good option for applications requiring tight concentricity/runout. This method performs well in low/moderate torque (20-30 lbs x in.) applications, even for high rotational speeds. Good for devices where space constraint is a concern.

Disadvantages: Requires very precise tolerances on the bore of the pulley and on the pilot surface of the shaft. Not all combinations of materials provide the same torque capacity of the press-fit

Shaft-lock type is a very robust way to connect a pulley to a shaft; good for high-speed applications as well. It is recommended for mechanisms where axial space is of concern; doesn't require extremely precise tolerances on the pilot surfaces. These devices are made of various types of metals (steel is preferred).

Disadvantages: a more expensive option (requires additional component, the shaft-lock). Some of the shaft-lock devices, especially the heavy duty ones, are not easily installed and even more difficult to uninstall.

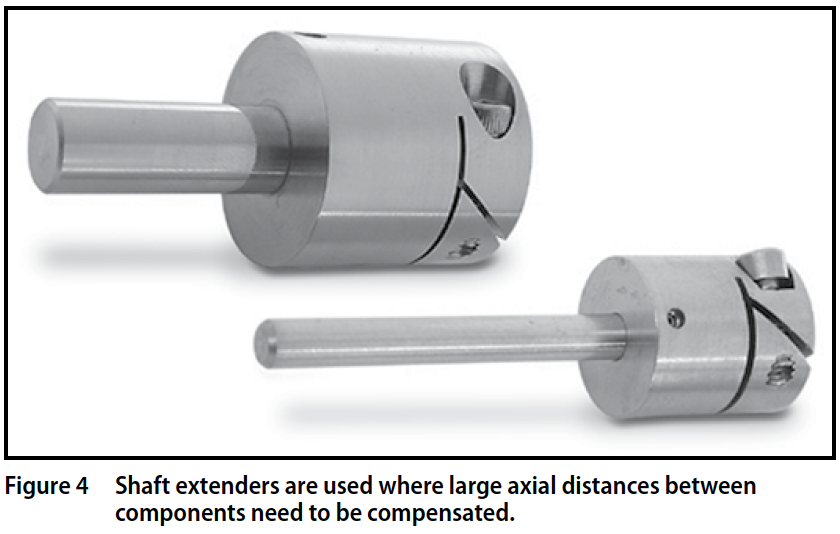

Shaft Extenders are used where large axial distances between components need to be compensated. When produced in stainless steel they provide the best performance for high-torque (70-80 lbs x in.) and high-speed applications.

Disadvantages: requires high precision shafting and very tight concentricity bore and the shaft O.D.

Clamp type requires additional clamp to connect a split hub pulley and a shaft. Clamps come in a variety of configurations; balanced clamps are used for high-torque applications.

Disadvantages: additional component - the clamp. Requires controlled tolerances on pilot surfaces, some of the constructions are difficult to assemble. Usage of clamps has declined as easier to use connecting methods have been developed.

Applications:

- Set-screw: in mechanisms used for shop manual tools

- Fairloc: aerospace, avionics, medical, printing, scanning devices

- Shaft-lock: power tools, oil industry

- Shaft extenders: drilling devices

When attaching the pulley to a shaft you have a number of choices; one method may work better in your application than another. It is important to have a basic understanding of your drive system and keep the following points in mind: torque, speed requirements, accessibility, material and cost.

Darbar Company is Pakistan's leading Power Transmission Solution provider, mainly specializing in Bearings, Roller Chains and Timing Belts. Give us a call to find out what products we carry.

The original article can be found at the Power Transmission Engineering blog here

3 Warning Signs of V-Belt Premature Failure

V-belts are the most common type of belt today, and as their name suggests, their cross-sectional shape comes in the form of a “V” and are widely used in industrial, automotive, commercial, agricultural, and home appliance applications. V-belt drive isa popular option to many as it is economical, easy to install and requires no lubrication.

V-belts are the most common type of belt today, and as their name suggests, their cross-sectional shape comes in the form of a “V” and are widely used in industrial, automotive, commercial, agricultural, and home appliance applications. V-belt drive isa popular option to many as it is economical, easy to install and requires no lubrication.

To ensure that your V-Belts have a longer lifespan, it is important that you look out for the following warning signs of premature belt failure:

1. Improper Seating of V-Belt on Sheave

Theincorrect seating of V-belt installation is one of the of the red flags that can cause early damage to your belt. When the seating is too deep, it indicates that the belt section is too small or there is a worn sheave; when theseating is too high, the belt section may be too big.

2. Watch Out For Its Tension

During multiple belt application, having a big difference in the tension of each belt is another early sign of premature belt failure. There is a tension at which belt experiences its optimum service life. Anything above or below its tension results in a decrease in belt life.

3. Seeing Smoke During Operation

If you see burning during the belt drive process, do not panic. Smoking is an indication that there is a slip between the V-Belt and sheave due to either a low belt tension or worn sheave. When sheaves become worn, the sides of the sheave angle start to cup and have a concave appearance and the belt has less area contact with the sheave and slips.

Original article can be read at SLS Blog: http://bit.ly/2liVBKn

Darbar Company provides all kinds of V-Belts and Timing Belts. Contact one of our sales representative to find out which type of belt will work best with your equipment. You can send us your inquiry here

Darbar Company is an authorized distributor of Gates Timing Belts. For more information on what products we sell check our products page here