3 Bearing Killers and How To Stop Them: Part 1

Bearing failure can grind your operations to a halt, resulting in significant lost time and production. Here are the first three of six common factors that can cause bearings to fail, and what you can do to prevent them.

Bearing failure can grind your operations to a halt, resulting in significant lost time and production. Here are the first three of six common factors that can cause bearings to fail, and what you can do to prevent them.

No matter the application, the proper functionality of bearings is essential to optimize operations. Whether a bearing is a cylindrical, spherical, ball or roller bearing, its precise design and engineering require special attention to ensure it’s working correctly. Bearing failure means downtime, maintenance and a major blow to operational efficiency—and in many cases, that failure can be easily prevented.

Applications requiring dependable bearing operation are countless but common reasons for bearing failure are fairly narrow. Though improvements in technology, design and user training have helped reduce failure incidents, understanding how and why bearings commonly fail is critical.

Here are the first three of six common reasons for bearing failure and how to make sure they don’t bring operations to a halt:

#1: Improper Handling and Installation. Proper bearing care begins when the bearing first arrives at the application site. From the shipping dock, to storage, to installation, proper handling and care is necessary to ensure the bearing will function as intended.

Even the smallest imperfections can shorten a bearing’s lifespan, and many nicks and scratches occur before the bearing is even put into use. Damage can occur when a bearing is in storage; therefore, if stocking bearings prior to needing them on your plant or shop floor, make sure the proper storage techniques are being followed. Don’t remove the bearing from the manufacturer’s original packaging unless absolutely necessary; if it must be removed, store in anticorrosive wrapping, and apply the appropriate preservatives to the bearing first.

When ready to install, cleanliness is critical. Technicians should perform the work in as clean an environment as possible, using clean tools, and should take care not to remove any of the preservative coating. Carelessness is the most common cause of damage to the bearing throughout the installation process. Poor handling while removing the outer races from housings or wheel hubs, for instance, can leave burrs or high spots in outer race seats. Tools can inadvertently gouge housing seats, leaving imperfections that can increase rolling contact stress, limit fatigue life or fracture machine components in the worst cases—all the more reason to ensure your installation processes are conducted with care and precision.

#2: Improper Lubrication. Lubrication is the lifeblood of proper bearing operation, and it is dependent on several variables in any given application.

Most bearing manufacturers and suppliers will recommend a specific lubricant type, grade, supply system, viscosity and additives for the application. They will also provide the amounts of lubricant that should be used and how often it should be changed or replenished. More application-specific recommendations and details including loading, speeds and sealing are often included as well.

Just like the bearings themselves, lubricants must be stored properly. Shelf life, temperature, filtration and other precautions will again be available via your bearing/lubricant supplier.

Technicians should adhere closely to these recommendations—bearing compatibility and performance depend on it. Underfilling and overfilling, mixing and matching lubricants, and changing lubrication at irregular intervals can all result in significant damage that can bring your operations to a standstill.

#3: Overheating. A primary function of proper lubrication is to prevent the overheating of bearings and associated components. Overheating can lead to damage and ultimately breakdown for a variety of reasons related to the lubricant. Higher temperatures can be caused by ambient temperatures, process temperatures, and severe operating conditions that can increase rolling contact friction. Likewise, lower ambient temperatures can have a negative effect—lubricant viscosity increases at lower temperatures and can cause improper flow and therefore compromise protective benefits. Your lubricant supplier can provide the ideal operating temperature change.

Technicians can and should do more than simply follow supplier instructions to ensure lubricants are performing properly and keeping their bearings at the appropriate temperatures. Be vigilant about monitoring bearings for heat-related trouble signs that can impact lubrication and ultimately the bearing itself. In order of severity, these symptoms include:

- Bearing discoloration. This will occur as a result of metal-to-metal contact, a sure sign of a lubrication issue. Look for gold and blue discoloration on races and rollers; lubricant staining is common in mild cases, while the metal itself may be discolored by excessive heat in worse cases.

- Peeling and scoring. Marks cut into the metal or peeling metal indicate a more severe lubrication/heat issue and should be addressed immediately.

- Localized scoring. This occurs due to the breakdown of the lubricating film which causes direct contact between components. Address immediately.

- Cumulative wear. High localized heat can alter the geometry of the bearing itself, resulting in a locked-up bearing that can cause significant additional damage.

Read the original article at: http://bit.ly/2m8jZgo

Follow bearing tips to get the latest tips on bearings

Demystifying Bearing Fit Practices

If you enjoy ambiguity and uncertainty, there are few better places to start than fitting a small ball bearing with tight clearance. Just to keep things simple, I’ll use Koyo’s (JTEKT) main Ball & Roller Bearings catalog for the technical information. All full-size bearing catalogs will have the same information.

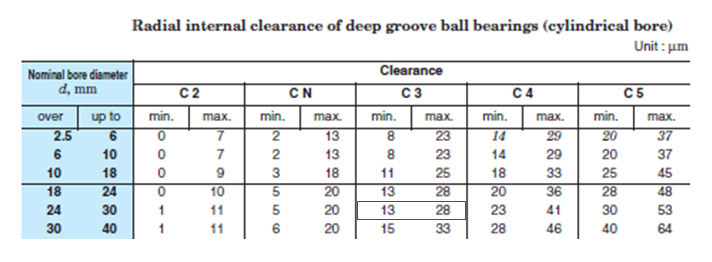

The place to start when determining fit is with clearance. When dealing with ball bearings, the term “clearance” always means radial internal clearance, whereas when we preload tapered bearings, we are usually talking about axialpreload/endplay (Fig. 1). For your reference, axial clearance is around 10x the distance of radial clearance.

If you enjoy ambiguity and uncertainty, there are few better places to start than fitting a small ball bearing with tight clearance. Just to keep things simple, I’ll use Koyo’s (JTEKT) main Ball & Roller Bearings catalog for the technical information. All full-size bearing catalogs will have the same information.

The place to start when determining fit is with clearance. When dealing with ball bearings, the term “clearance” always means radial internal clearance, whereas when we preload tapered bearings, we are usually talking about axialpreload/endplay (Fig. 1). For your reference, axial clearance is around 10x the distance of radial clearance.

Let’s just walk through a quick example with my favorite bearing, i.e. — 6205. When ordering these you must know what clearance you are ordering; this will usually be indicated somewhere in the title. Even though there is a “normal” clearance designated with CN, C3 is by far the most common clearance.

k great — you now have a C3 6205; what does that mean? Fortunately, ISO ball bearings are very standardized, so you can find clearance tables similar to Table 1 just about anywhere online or in any catalog, and it will be the same for any brand. Since a 6205 has a 25 mm bore (multiply the last digit by 5), under the C3 column you see that we have a clearance range of 13 – 28 microns (µm). This is basically how much room we have to work with. Unlike tapers, we do not want to preload a ball bearing. There are a few situations with lightly loaded bearings where you can add a light axial preload via spring or similar method; but we will never try and radially preload a ball bearing.

For most normal ball bearing applications, you will want an interference fit on one ring and leave the other ring loose or leave the other ring as a loose fit (aka clearance fit). There are three reasons for this: 1) there is not enough internal clearance in the bearing to press both rings; 2) one slip ring prevents over-constraining the bearing system; and 3) without special tooling you will need to press one of the rings through the bearing, which is a huge mistake (e.g., pressing the bearing into the housing with the shaft). You will damage the bearing by doing this. If you need to constrain the loose ring, you need a mechanical retainer such as a snap ring.

When possible, the rotating ring should have the interference fit. The only reason for this is that the turning ring is mostly likely to try to walk around the shaft due to inertial effects. Some light walking or creeping is harmless as long as you aren’t moving material or creating heat. For our 6205 example, let’s say we are pressing onto a rotating shaft, which carries a stationary load.

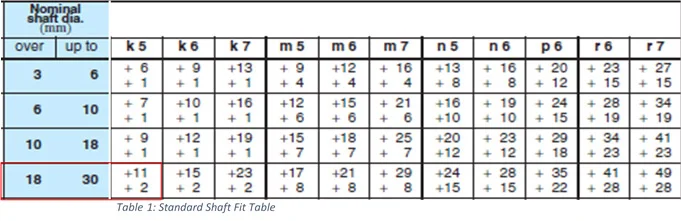

Table 2 gives us a recommendation, but we still need to do more work. If we are working with a normal load (6-12 percent of the dynamic load rating), a k5 shaft fit is recommended. Usually hidden somewhere in the appendices there will be standard shaft and housing fit tables. As shown in Table 3, our 25 mm shaft diameter has a k5 fit of +2 / + 11 µm. These dimensions are applied to the diameter class of the bearing (not the average diameter). For instance, a 6205 has an inner ring diameter tolerance of -10 µm, leaving the true average around 24.995 mm, rather than 25.0. Fit tolerances are applied to 25.0 mm. For our 6205 the recommended shaft is 25 +2/+11. Sometimes unilateral tolerances can make for easy proofing (rather than 25.002/25.011); your choice.

You may quickly realize that you have been handed a 9-micrometer tolerance to work with. This is tighter than the bearing tolerance that you are buying and, for most places, unrealistic. A k7 or k8 is the more likely reality for most places. You can see that all of the fits in the k series have a minimum press of 2 µm. I will often use 5 µm as a minimum threshold for a “press fit,” but I’m not going to argue about 3 µm. Where the hand-wringing starts is when we look at the stack-up for these fits. Again recalling that our inner ring has a -10 µm tolerance, a k5 leaves with a fit range up to 21-µm interference. All things considered, the residual clearance ranges from 11 µm interference to 26 µm clearance.

But what about the clearance?

Ok, there is a slight caveat; you can have a little radial preload before you fall off the edge. The reason I recommend not trying to design this in is, as you can see, trying to avoid any chance of preload would leave you with a very loose shaft on the other end; that will create problems for you. As we are threading this needle, the small amount of potential preload at the limits can be tolerated (more so than an excessively loose shaft).

Now let’s see how this looks with a more realistic range. For me, I would target about +5/+30 for this application. That puts our effective clearance at 16 µm interference to 24 µm clearance. If you are looking for a rule of thumb for how far you can play this game, I like to have my clearance range about 2x the interference range. Statistically, this will rarely get you into the fringes of your clearance window. My +5/+30 would be a few microns on the tight side, but with a bearing that has a healthy life margin, there is nothing to worry about. If I were pushing the life limits of the bearing, I might back down to +2/+27. Many bearing suppliers will agree with this approach; some get nervous when relying on statistics. This is just the reality of bearing fits.

The housing fits are quite a bit easier. Start with a line to line fit and let your tolerance decide the upper end. So for my 6205 with a 52 mm outer diameter I am going to set my lower housing diameter at 52 and the upper end is going to be whatever I can hold. Easy breezy.

Follow these simple rules and your fits will be perfect:

- Know your bearing clearance, dimensions and tolerances up front.

- Press fit one ring (preferably the turning ring) and slip fit the other. Follow the tables for guides, but also double-check your stacks to make sure you aren’t running more than ~ 30% into potential preload.

- Start line to line on the housing. Too loose of a housing can create alignment and/or noise problems. Sometimes too close of a housing fit can be difficult to install. Adding a little oil to the outer ring is common practice. Leave opening up the diameter as a last resort.

Read the original article here: http://bit.ly/2mdH8gz

Power Transmission Engineering is a great blog to follow to keep up with industry insights!

Bearing Maintenance From Start to Finish (Part 3)

In service, sufficient lubrication is essential. Maintenance goals: Deliver the right lubricant in the right amount at the right time.

Among lubricant delivery methods, manual lubrication (with grease gun) typically can present major challenges for maintenance technicians if the appropriate tools, practices, and knowledge are absent – and reliability can further be affected by under- or over-greasing. As a practical alternative, automatic lubrication can be employed to provide quantities of clean lubricant on a regular basis, while increasing safety and saving time for staff. Ready-to-use or tailored systems can be engaged, depending on application, lubricating points, and similar considerations.

For any type of bearing in rotating machinery, applying best maintenance practices and using the correct enabling tools can help contribute to maximum bearing service life.

Bearings should always be properly stored, mounted, adequately lubricated when and where required, monitored, dismounted, and ultimately inspected to uncover root causes of any damage.

While particular applications will present unique factors influencing a bearing’s service life, the following maintenance-oriented guideline can substantially improve the life of bearing.

Turning to bearings in service

In service, sufficient lubrication is essential. Maintenance goals: Deliver the right lubricant in the right amount at the right time.

Among lubricant delivery methods, manual lubrication (with grease gun) typically can present major challenges for maintenance technicians if the appropriate tools, practices, and knowledge are absent – and reliability can further be affected by under- or over-greasing. As a practical alternative, automatic lubrication can be employed to provide quantities of clean lubricant on a regular basis, while increasing safety and saving time for staff. Ready-to-use or tailored systems can be engaged, depending on application, lubricating points, and similar considerations.

Over time, the lubricant in a bearing arrangement gradually will lose its lubricating properties due to mechanical work, aging, and/or the buildup of contamination. This underscores a maintenance-related necessity for grease to be replenished or renewed and for oil to be filtered and changed at regular intervals to help promote maximum bearing service life.

To gain long bearing life it is imperative to determine the condition of machinery and bearings while in operation. This can be accomplished with a process known as “condition monitoring.”

Condition monitoring allows for the repair of components detected as problematic prior to their failure. This is accomplished by performing condition-based maintenance. The approach not only reduces the possibility of catastrophic failure, but also allows plant personnel to order parts in advance, schedule manpower, and plan unrelated repairs during the downtime.

The most significant machine-condition parameters to help monitor the health of a bearing include (in no specific order) noise, temperature, speed, vibration, and alignment. A variety of measuring instruments will enable users to analyze all factors.

When a bearing must be taken out of service, for whatever reason, proper dismounting practices should be followed.

One reason for dismounting an old bearing is to replace it with a new one. When proceeding, care must be taken not to damage the shaft in the process, which can result in compromising a machine's efficiency. A damaged shaft can greatly influence the service life of the new bearing.

Another reason to dismount bearings is for maintenance or replacement of other machine components. Since these dismounted bearings will be mounted again (unless they are damaged during dismounting), proper dismounting methods and tools should be enlisted. Choice of tools will depend on bearing type, size, and fit.

In situations where a bearing must be replaced due to premature failure, detective work focusing on bearing and grease analysis can help point to root causes. Among common root causes: inadequate lubrication, contamination, errors in mounting/dismounting, and/or electrical damage. Pinpointing the actual cause(s) will help prevent a repeat of history.

When it comes to bearing maintenance, every decision and practice can impact a bearing’s performance, reliability, economy, and service life. Partnering with an experienced bearing manufacturer can open the door to the knowledge and technologies that will support maximized bearing life and reduced maintenance time, labor, and costs.

Bearing Maintenance From Start to Finish (Part 2)

Because they are precision components, bearings should be handled and mounted with care using correct techniques and technologies. An estimated 16% of all premature bearing failures are caused by poor fitting, usually using brute force, and being unaware of the availability of the suitable mounting tools and methods.

For any type of bearing in rotating machinery, applying best maintenance practices and using the correct enabling tools can help contribute to maximum bearing service life.

Bearings should always be properly stored, mounted, adequately lubricated when and where required, monitored, dismounted, and ultimately inspected to uncover root causes of any damage.

While particular applications will present unique factors influencing a bearing’s service life, the following maintenance-oriented guideline can substantially improve the life of bearing.

Mounting and Greasing

Because they are precision components, bearings should be handled and mounted with care using correct techniques and technologies. An estimated 16% of all premature bearing failures are caused by poor fitting, usually using brute force, and being unaware of the availability of the suitable mounting tools and methods.

The primary methods for proper mounting of a bearing are commonly referenced as “cold” or “hot,” consistent with their enabling technologies. Cold mounting, or mechanical mounting, generally is recommended for small and medium sized bearings (with outside diameters up to 4 inches); methods involving heat mounting will be appropriate for relatively larger bearings; and hydraulic techniques should be considered when mounting especially large bearings. Tools have been developed to accommodate each particular method.

In cold mounting, the misguided practice of using a standard hammer and pipe for the job has long been discredited due to the damage that can occur. This practice can cause debris to enter the bearing or, if not done properly, a pipe can slip and impact the internals of the bearing. Best practice: The use of fitting tools to eliminate harmful brute force and apply the proper force to both bearing rings to isolate the rolling elements from impact force for a more reliable installation.

Hot mounting, where the bearing is pre-heated, provides a practical solution to allow for a bearing’s expansion and subsequently easier installation, while maintaining specified interference fit after the job is completed. Induction heaters can integrate various features to help prevent bearing damage during the heating process. These solutions stand in direct contrast to less effective (and potentially dangerous) methods, including an open flame, hot oil baths, and ovens or hot plates.

For the larger sized bearings, hydraulic techniques and compatible tools and equipment deliver the goods. Hydraulic techniques allow for more control and further help to maintain precision, accuracy, and repeatability; minimize the risk of damage to bearings and shafts; require less manual effort; and promote greater operator safety.

Choosing the proper bearing lubricant will help bearings perform as long as intended. Good lubricants primarily provide a separating film between a bearing’s rolling elements, raceways, and cages to prevent metal-to-metal contact and undesired friction that otherwise would generate excessive heat that could lead to adhesive wear and subsequent metal fatigue and spalling of the bearing contact surfaces. The proper lubrication further acts to inhibit wear and corrosion and helps guard against contamination damage.

Half of all bearing failures attributed to poor lubrication are caused by selection of an inadequate grease type for the operating conditions or to mixing incompatible greases with different properties. Therefore, it is imperative for optimized bearing performance that the correct type of grease be selected to deliver the necessary base oil viscosity in the proper amount at the prevailing operating temperature.

Grease has traditionally served as the preferred lubricant for rolling bearings. The practical benefits become apparent: Grease is easy to apply, can be retained within a bearing’s housing, and offers protective sealing capabilities.

Greases are classified by their stiffness or consistency according to the U.S. National Lubricating Grease Institute (NLGI) and are graded from NLGI Class 000 (very soft) to 6 (very stiff). These classifications are based on the degree of penetration achieved when a standard cone is allowed to sink into the grease at a temperature of 25°C for a period of five seconds.

Grease composition is roughly 85% base oil (mineral or synthetic) and 15% soap or thickener and will vary from grease to grease. The base oil is the oil inside the grease, which provides the lubrication under the operating conditions. The soaps or thickeners hold the oil and/or additives together to enable the lubricating grease to function and, in some cases, may enhance the lubricant film. (The type of thickener gives the grease its typical characteristics, retaining the oil in a similar manner to a sponge retaining water.) Additives provide additional characteristics such as wear/corrosion protection and friction-reducing effects.

By varying oil viscosities, soap, and additives users can benefit from greases with distinct characteristics able to suit particular applications and operating conditions.

Bearing Maintenance From Start to Finish (Part 1)

Bearings should always be properly stored, mounted, adequately lubricated when and where required, monitored, dismounted, and ultimately inspected to uncover root causes of any damage.

While particular applications will present unique factors influencing a bearing’s service life, the following maintenance-oriented guideline can substantially improve the life of bearing.

For any type of bearing in rotating machinery, applying best maintenance practices and using the correct enabling tools can help contribute to maximum bearing service life.

Bearings should always be properly stored, mounted, adequately lubricated when and where required, monitored, dismounted, and ultimately inspected to uncover root causes of any damage.

While particular applications will present unique factors influencing a bearing’s service life, the following maintenance-oriented guideline can substantially improve the life of bearing.

Making the initial right moves

From the outset, proper storage is critical. Bearings should always be stored in a cool, clean, low-humidity environment free of dust, shocks, and vibrations. (For these reasons, storing bearings directly on a floor should be avoided.) They should ideally be stored flat rather than on end and be kept in their original, unopened packages until just before mounting. If kept in a standing position, the likelihood of false brinelling (wear of the raceways and rolling elements caused by residual vibration) increases significantly. False brinelling is much less likely to occur in bearings laying flat.

In the cases of sealed or shielded types of bearings, operators should be cautious when storing them over long periods of time. The lubricating properties of the grease used to fill these types of bearings may deteriorate, causing potential lubricant-related problems when a system is up and running. (Most bearing manufacturers have specific shelf-life limits, based upon the greases used in their bearings.)

The importance of cleanliness cannot be over-emphasized. All bearings should be kept clean, because contamination and corrosion will shorten the life of any bearing.

When a bearing is ready to be mounted, maintenance staff should confirm that shaft and housing are clean, undamaged, and dimensionally accurate (with proper fit and tolerance); lubricant is clean and correctly specified; necessary tools and equipment are on hand, and safety precautions are in place.